The HP Latex 3000 was designed as a production machine but can it handle both image quality and high speeds? Nessan Cleary puts it to the test.

Last year we tested HP’s 26500 entry-level latex printers but there are also several larger models so we’ve been back to put the top of the range Latex 3000 through its paces. This is a fairly large roll-to-roll printer, capable of taking media up to 3.2m or two rolls up to 1.6m each side by side.

This was the first of HP’s third generation latex printers to feature an ink that cures to a tougher finish than previous models. Jane Rixon, channel business manager for HP’s large format printers, says that the scratch resistance is similar to that of a solvent printer. But unlike a solvent printer, the latex prints are immediately ready for laminating with no need to wait for them to outgas.

There are six colours - CMYK plus light cyan and light magenta - which are supplied in 5 litre boxes that sit on top of the machine. It is a water-based resin ink, which requires a certain amount of heat to cure. Thus it takes a couple of minutes to come up to temperature at the start of a print run and you have to wait for it to wind the prints back and finish curing when the printing is done. That said, it seemed to be a lot less sensitive to heat than the L2850 that we tested last year, with no need to tweak the profile to achieve the right balance between the amount of ink laid down and the amount of heat needed to cure it.

The third generation machines also use an optimiser, essentially a clear primer that is laid down at the start of a print via one of the printheads so that it only goes where the image is required. Rixon says that its purpose is to help pin the ink so that it cures more quickly, which is a crucial addition to this printer as it allows it to run at the higher speeds.

The thermal printheads are HP’s 881 - classed as consumables. They are rated to last for just 12 litres but Rixon says they should last for around 40 litres and that at least one customer has pushed the heads to 100 litres. She adds: “The machine gives you a warning but you can carry on based on the quality and application you are trying to achieve.”

There are seven heads in total, which are set up with two interlaced between cyan and black, two for light cyan and light magenta, and two for the magenta and yellow ink, with the seventh just for the optimiser.

The heads use a fixed 12 picolitre drop size and give up to 1200dpi resolution, which HP says will produce 77m2/hr indoor quality and up to 120m2/hr for outdoor applications. It’s a fixed resolution with the different print modes varying the number of passes. Thus the highest quality uses 14-passes for high quality backlits at 35m2/hr while the fastest billboard mode takes just two-passes and runs at 180m2/hr. However, Keyboard Graphics in Swanley (where this test was conducted), did point out that the head traverses the whole carriage width even if printing a narrow roll, which inevitably slows it down.

It takes standard flexible substrates including banners, self adhesive vinyl and canvas and there’s a mesh kit for handling textiles, though it’s not really sold as a textile printer. It can take a single roll up to 160kg, though you have to be careful that the spindle doesn’t catch in place as it’s all too easy to drop on your foot. Media can be up to 15mm thick and there’s an optional carriage height setting that will allow media up to 80mm.

Maintenance seems fairly simple - the touchscreen interface on the front indicates when the heads need cleaning and there’s a wizard to walk operators through the process with access to video tutorials online. However, you do have to do the head cleaning and it does mean having to boot the machine up and down, which takes time and can be frustrating when the operators are busy. There are fixed service intervals such as at 100 litres and 600 litres, with an engineer call out after printing five million litres of ink.

On test

For this test we visited Keyboard Graphics in Swanley, Kent, who graciously made time for us despite having an obviously busy schedule. Keyboard mainly specialises in exhibition graphics and also has a Latex 850 and two of the smaller HP Scitex flatbeds.

For this test we used a self adhesive vinyl, which gave us a choice of four, six or eight passes. We have two A0-sized test charts - one with mainly solid Pantones and one with mainly photographs - and  normally print in both the highest resolution available to gauge the image quality of the printer and a standard production mode to get an idea of general productivity. Keyboard normally uses the six-pass mode for most work but we opted to use both the eight-pass and four-pass modes for our tests.

normally print in both the highest resolution available to gauge the image quality of the printer and a standard production mode to get an idea of general productivity. Keyboard normally uses the six-pass mode for most work but we opted to use both the eight-pass and four-pass modes for our tests.

The machine took two minutes to warm up from cold with a further 20 seconds to lay down the optimiser before it started printing. The mainly photographic chart took two minutes in four-pass mode, and three minutes in eight-pass, while the mainly Pantone chart took 1.35 minutes in four-pass mode, and 2.30 minutes in eight-pass mode. Once we’d finished there was then a further 5.35 minutes for the prints to cure.

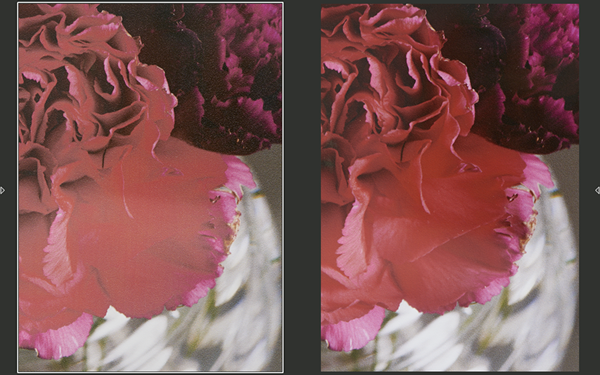

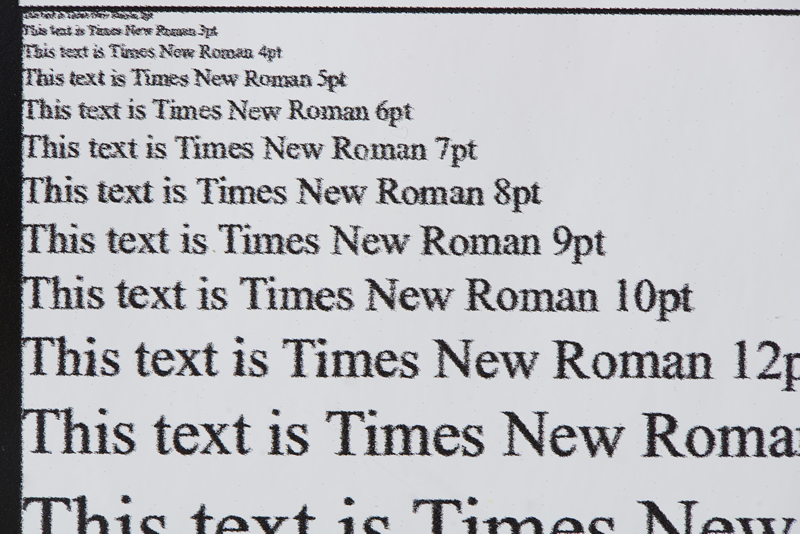

The four-pass mode is good enough for banner work and anything that's going to be viewed from a distance but is definitely lacking image quality when viewed up close. Overall the images are grainy and some of the brighter colours are a little washed out. The Pantone swatches are all present and correct but lacking any real vibrancy. Worse still, the petals of the red carnations in one photograph have merged together as there's no detail to distinguish them. There's also some slight banding in the blue gradient panel. The text is a little fuzzy, barely legible at 4pt and not really comfortable to read beyond 6pt.

There’s a considerable improvement in the eight-pass mode, with the colours now appearing bright and punchy. However, the resolution is only slightly improved with the text still only legible down to 4pt there the letters are more defined. The white text on black panel has fared worse and is only really legible at 7pt. Still, Keyboard have kept an older, smaller L2550 for those jobs that require finer text.

Conclusion

The machine costs £230,000, which includes installation, training and a year’s warranty plus a further Ramp Up training, whereby an engineer will come back after a couple of weeks to make sure that the machine is running properly, that the operators are comfortable using it and to offer further training. It’s sold in the UK through a dealer channel, led by Art Systems, which is also responsible for the servicing. The ink, and the optimiser, come in five litre boxes and each cost £315.79.

The Latex 3000 was designed as a production machine and it was obvious from our visit to Keyboard Graphics that it’s fulfilling this role nicely. The printing was fairly straightforward – once the files were Ripped and sent to the on-board controller the Latex 3000 churned our files out fairly quickly without any fuss.

The four-pass mode would certainly be good enough for a bill board or outdoor banner meant to be viewed at a distance, but the image quality is definitely better at eight-pass, as you would expect, with very little speed sacrificed to achieve this. There were certainly no complaints about the machine from the staff at Keyboard Graphics.