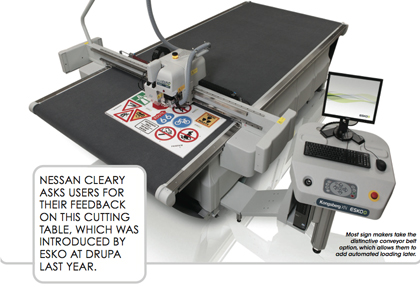

Nessan Cleary asks users for their feedback on this cutting table, which was introduced by Esko at Drupa last year.

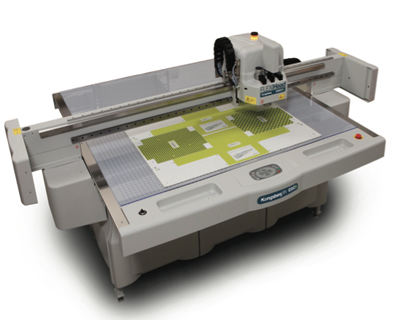

Most people who invest in a UV flatbed printer quickly find that a cutting table is an essential accessory to keep jobs moving through production and prevent bottlenecks. These tables can handle most materials from vinyl through to acrylic and many now sport powerful routing heads for dealing with the tougher substrates such as aluminium. There are several to choose from but Esko's Kongsberg tables have established themselves as one of the market leaders. Esko has a bewildering array but the XN series, introduced at last year’s Drupa show, has proven popular.

One user is Design4Print, based on Canvey Island. This is a general commercial printer with a dedicated large-format department printing everything from vinyl to dibond. The company had originally planned to buy a Zund G3 but it was taking so long to organise that it ended up opting for the Kongsberg XN, which it has been using for the last 18 months.

Chris Sparrow, signage director, appreciates the flexibility of the XN, which can take an 8 x 4ft board, or longer, thanks to its conveyor belt design. He points out: “You can put an 8 x 4ft on a roll on the conveyor belt but you can’t cut on the edge of the sheet,” acknowledging that there are bolt-ons available to expand the cutting area.

Sparrow says that one of the best features is the multi-cut tool which saves having to load different tools for different jobs. Design4Print invested in two extra tools - a creaser and a static drag knife.

Design4Print uses Esko’s iCut software, which links together with an Onyx Thrive workflow driving two Océ Arizona flatbed printers. Sparrow explains: “We edit a cut path as a separate layer, drop that to the file which Thrive recognises and prints out the cutter registration marks, which the magic eye reads.”

The Kongsberg has proven easy to service and maintain, so much so that Sparrow didn’t bother to take out a service contract after the first year. He says that very little goes wrong with cutting tables, and that once you’ve been working with the machine for a while and know how it works then you can sort out most problems yourself.

But, one thing that did catch-out Sparrow, was the need to have a compressed air supply, which was an unexpected cost.

He says: “That was the only thing upon install that we were unhappy about but they did rework things so it cost us very little to do that.”

an Onyx Thrive workflow driving two Océ Arizona flatbed printers. Sparrow explains: “We edit a cut path as a separate layer, drop that to the file which Thrive recognises and prints out the cutter registration marks, which the magic eye reads.”

The Kongsberg has proven easy to service and maintain, so much so that Sparrow didn’t bother to take out a service contract after the first year. He says that very little goes wrong with cutting tables, and that once you’ve been working with the machine for a while and know how it works then you can sort out most problems yourself.

But, one thing that did catch-out Sparrow, was the need to have a compressed air supply, which was an unexpected cost.

The machine has been very easy to operate, so much so that Design4Print has been able to train other members of staff to run it. Overall the company has been very happy with its Kongsberg XN, not surprising when Sparrow says: “It’s increased our production ten-fold.”

Another user is Colouration, based near Wimbledon, which is also an established litho printer that now has a dedicated digital wide-format department. Colouration already had several cutting options in the shape of platen die cutters that were mainly used for long-run and litho jobs, as well as a Tekcel router and an elderly Zund 1250. But a year ago the company bought a Kongsberg XN24 as part of a wider investment that also included a second Océ Arizona flatbed printer.

Dave Mays, operations manager, says he was attracted to the Kongsberg by the fact that Esko also developed its own design software as well as its heritage in 3D design.

Colouration mainly uses the Kongsberg for cutting soft boards and vinyls. Consequently the company has a good selection of creasing and cutting tools, including the power head, but doesn’t have any need for the routing tools. Mays says that one reason for choosing the Kongsberg over buying another Zund was the ease of changing the tools.

He feels that the Kongsberg has been good value for money, having automated a lot of cutting operations that would otherwise have been done by hand. He says that while wide- format is a small part of the company: “as we have expanded the Kongsberg has been a must.” He adds: “it’s a very easy tool to work with. It’s a very well-built machine.”

About the product

The XN has been designed to be highly productive, with a decent size bed but is not as automated as the more expensive XP series. It is an extremely flexible platform, available in seven different sizes ranging from 1680 x 1270mm to 2210 x 6550mm. There are several options, including a distinctive conveyor belt for automated material feeding, as well as a sheet feeder that can load sheets from a stack onto the conveyor belt and a roll feeder.

The XN has been designed to be highly productive, with a decent size bed but is not as automated as the more expensive XP series. It is an extremely flexible platform, available in seven different sizes ranging from 1680 x 1270mm to 2210 x 6550mm. There are several options, including a distinctive conveyor belt for automated material feeding, as well as a sheet feeder that can load sheets from a stack onto the conveyor belt and a roll feeder.

There’s a wide range of different heads available, including a new 3KW multiCut HP milling spindle which is said to be three times faster than the previous tool and particularly useful for heavier materials such as acrylic or MDF. There are a number of tools including v-notching inserts for solid board and corrugated boards and a Braille tool

It comes with the iCut suite for managing the files between the printer and cutter. There are several parts to this including: Preflight, to ensure that jobs will print correctly; Layout, that optimises the best use of the sheet for the least waste; Automate, which governs the whole workflow; and Vision Pro for die-less cutting contours. Other software includes ArtiosCAD for 3D designs of things like POP displays.

Alternatives

ZUND

The main alternative is the Zund G3 series, available in a range of different sizes from 227 x 160cm up to 321 x 320cm. There are extension tables to cope with bigger materials. They can take up to three modules, including a Universal module designed to hold the full range of tools that Zund provides. There’s also a 1kW router module, with automated dust extraction, as well as a Punch module, capable of punching up to 10 holes per second, and a Marking module that takes a number of drawing and plotting pens. There are several specialised tools, including a Universal cutting tool, two oscillating tools and two creasing tools, as well as tools for kiss-cutting, bevel cutting and V-cutting. The G3 series will handle both roll and board materials and can cut materials up to 50mm thick.

MIMAKI

Mimaki makes the CF2 series: there are two models with cutting areas of 117 x 90cm and 177 x 120cm. They can cope with materials from vinyl to corrugated boards. There are two heads available, which take a broad range of blades. The TD head takes a tangential head that can steer blades as it cuts and is capable of both die cutting and half cutting. The RC head can take both a reciprocal head for materials such as corrugated board and cardboard, as well as a tangential head.

DYSS

Dyss sells the X7 series, which ranges in size from 165 x 245cm to 325 x 305cm. They take substrates up to 50mm thick. There are two main cutting heads. The Triple head will hold three tools at once, while the Super head can hold a standard tool such as a drag knife or creaser and also has a routing spindle. There’s an optional conveyor system and it can be supplied with a K-cut vision camera system. There’s also a smaller X5 series, which are 1.3m wide and from 1m to 2.5m long.

KASEMAKE

From Kasemake is the KM7 series, which has a head that will take two tangentially driven tool modules and a pen. The available tools include an oscillating knife and a drag knife and there’s an optional router that will acrylic, wood and thin aluminium. There’s also a camera registration system.

{jathumbnail off}