…or let someone else mind it for you if you don’t have the in-house resource to ensure a robust and effective IT infrastructure. Andrew Metcalfe, managing director, of Opal IT runs through the key must-do’s.

Tech-Knowledge

The power of the media

Nessan Cleary takes a look at those substrates that can lead to new applications and new revenueopportunities.

Putting a smile on your face?

With DirectSmile now in EFI’s domain, should it become part of yours too? Sophie Matthews-Paul considers its place in the wide-format arena.

The end...

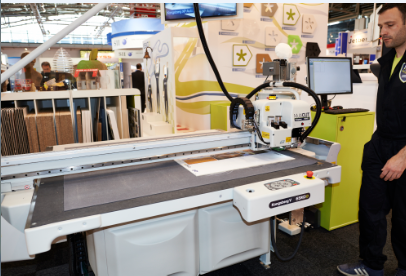

…could be the start of something big. Nessan Cleary brings you up to speed on cutting tables for finishing rigid materials.