Ink development is pushing ahead on wider fronts as OEMs and third party suppliers chase environmental and technology benefits as John Taylor reports.

There’s plenty of activity on the inks front as Epson announces ‘price harmonisation’ and Colourbyte swiftly follows up dropping its Epson ink prices by up to some 27%. So what’s occurring?

Look farther afield and there are developments, such as Smartridge slated for the market late 2015/early 2016, that may have caused a ripple. According to Image Alchemy MD Paul Banks, interviewed by Image Reports earlier in the year (http://www.imagereportsmag.co.uk/videos), this prospective refillable, chipped, fixed cartridge system obviates the need for environmentally unfriendly ink cartridges. The system boasts a mass of savings in cartridge based inkjets and will initially be targeting water-based inks and probably Epson printers. That aside, there are developments by OEMS with many machines switching to bulk ink systems and avoiding the cartridge issue altogether.

Mimaki for example, on bulk bottles for some time now, takes the total solutions view for the complete printer package, developing its printers, heads and inks for major benefits such as its MAPS4 reduced banding technology and MFD1 to reduce noise due to dithering through hybrid processing of patterns. Its new UJF-7151plus UV flatbed runs on LH-100 CMYK plus white and clear UV inks, PR-200 primer or LUS-120 CMYK and white plus light magenta and light cyan. Mimaki’s JFX200-2513 UV LED flatbed also runs on UV curable inks from front-loading 1l bottles – CMYK and white LUS-150 and CMYK, white and clear LH-100.

On the dye-sublimation front, new Mimaki TX500-1800DS Series volume production direct dye-subs are kitted out with dual 2l fast drying Sb300 ink bottles per colour. Sb300 is deemed a more affordable alternative to conventional ink, delivering brilliant colour reproduction with high fading resistance.

Certified for more…

Taking the corporate responsibility tack, Fujifilm now has bragging rights on Nordic Ecolabel certification for its Uvijet UV inks. Inca and Fujifilm have an ongoing development programme for UV curing inks for Inca printers. The development path for its ink formulations target best mix physical and chemical properties for each particular application.

Fespa Digital last year saw Fujifilm introduce four new inks. Uvijet OH is formulated for use with polyethylene and polypropylene materials now gaining in popularity for their recyclability. Uvijet OL low odour corrugated ink meets DiN EN 1230-1 for display and secondary packaging applications, with residual odours mimicking that of water-based flexo inks. Developed to increase the scope of applications on Uvistar grand-format UV printers, Uvijet QN white ink enables super-wide format posters to be illuminated to high advantage, for either day or night time applications.

Fujifilm’s new Uvijet KV thermoforming UV cured ink is for light industrial applications in its Acuity Advance Select and Acuity Advance Select HS mid-range flatbeds. This new formulation maintains high quality, vivid colour performance without compromising on print speed. Once printed on flat plastic, the sheet is thermoformed and then cooled. Notably, the ink boasts outstanding elongation properties up to 1000% when heated, returning to normal when cool. Says Fuji, this ink opens new opportunities for wide-format printers to explore more industrial applications, and generate new revenue streams from print technologies they already understand.

UV curables in demand

Pursuing the UV curable theme, Canon’s IJC257 UV curable ink, launched at Fespa, has since seen demand for it grow. Strong adhesion to different flexible, outdoor and indoor media is its big benefit, enabling a wide colour gamut on sign and display media such as satin matte. The ink is developed for the Océ Arizona.

“There has been pressure on the UV curable ink manufacturers to take a step up and consider adding multiple purpose ink for sign as well as display applications,” says Canon Europe wide-format printing group marketing manager Mathew Faulkner. The demand is for excellent adhesion, alluring surface features and great colour gamut benefits to drive the UV curable ink segment.

“Since retail industry occupies a significant market share,” Faulkner adds, “there has been a constant need for advancements to help ink add more value to the industry and deliver a valuable buyer experience.”

UltraChrome inks add to printer performance

New Epson SureColor SC-P large format printers - slated for availability from this month (November) - come in 24 and 44in, eight- or ten-colour, wide gamut versions. They also feature an advanced black and white mode. Running on new formula, eight-colour, UltraChrome HD pigmented inks, SC-P8000 and SC-P6000 boast improved lightfastness for colour and monochrome photographs, fine art prints, and standard proofs.

SC-P9000 and SC-P7000 provide the ultimate proofing solution running on Epson’s ten-colour UltraChrome HDX inks, complete with new violet. Delivering a wide spectrum of colour, these printers are said to achieve 99% of the Pantone colour library for accurate spot colour reproduction. Instead of running violet these versions are available with Light Light Black UltraChrome HDX ink for high-end photo and fine art applications.

Current Epson UltraChrome HD pigment ink research by Wilhelm Imaging Research is showing the new formulation of these pigmented inks can provide up to twice the WIR display permanence ratings of previous generations of Epson UltraChrome inks used with most Epson photo and fine art papers. Moreover, depending on the specific paper, WIR display permanence for monochrome prints made with UltraChrome HD inks running in Epson’s Advanced Black and White Print Mode will likely exceed 400 years.

“Epson continues to develop photographic printing and ink technologies that inspire photographers to print their art,” says Epson Professional Imaging Group manager Mark Radogna. “Utilising eight newly developed, high stability pigment inks, the latest Epson UltraChrome HD inkset offers professionals an amazing tool to produce stunning prints that will preserve their photographic legacy far into the future.”

Wilhelm Imaging Research founder and director of research, Henry Wilhelm adds: “With the increased Dmax, wider colour gamut, and reduced metamerism provided by the new Epson UltraChrome HD pigment inks – which taken together serve to significantly enhance the visual brilliance of both colour and black and white images – the increased overall permanence of the prints represents a significant contribution to photography. We look forward to posting print permanence test results for the new inks on a variety of media as the data become available. It is one of the realities of the print permanence testing field that the more stable the print, the longer the tests take to complete.”

Eco-Sol performers…

Roland’s Eco-Sol Max ink technology enhances performance for VersaStudio, VersaCamm, VersaExpress and SolJet inkjets and printer/cutters. Latest generation Eco-Sol Max 3 boasts overall better performance, faster drying, bigger cartridges and a lower price/cc of ink. This tough, scratch resistant ink is said to withstand outdoor environments for up to three years without lamination. It’s safe to use and easy to handle, is virtually odourless and needs no special ventilation equipment.

Durable, reliable and consistent colour from cartridge to cartridge, the Eco-Sol Max 3 ink range is deemed the perfect ink for productive and efficient printing. The eight-colour inkset, CMYK, light cyan, light magenta, white and metallic silver makes for high productivity output with its super-fast drying. Moreover, Roland says it will enhance print head life while ink running costs are kept low. It comes in 220, 440 and 500cc cartridges depending on colour.

With its wide colour gamut, it delivers rich, vibrant and solid colours that look stunning up close or from distance. Light black improves grayscale reproduction and the stability of skin tones or natural tints. And with the fast drying capabilities, prints can be handled immediately, says Roland, so that with a take-up unit, long, unattended print runs in high speed are an option.

Eco-Sol Max 3 readily bonds to a host of substrates, coated and uncoated, enabling versatility in range of output, from paper, vinyl, banner and canvas, to coated textiles, high gloss, heat transfer and more. An upgrade for existing Rolands to use Eco-Sol Max 3 is also available.

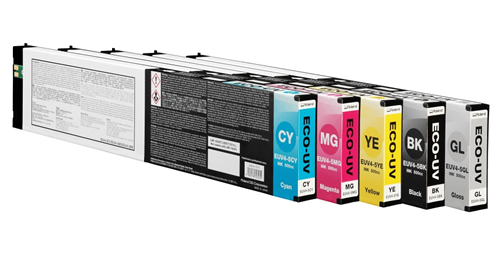

Roland’s brand new EUV4 eco-UV ink - for use with its VersaUV UV-LED inkjet printers - became available at the end of October.

Eco-UV ink is cured with UV light, enabling VersaUV users to print on an exceptionally wide variety of materials, and the addition of clear ink produces unusual textures and embossing effects. The new EUV4 features a change in chemistry that reduces odour and the shrinking of thin film materials like BOPP, PE and PET when curing.

In addition to a 220ml cartridge, a 500ml cartridge has been introduced (white ink is only available in 220ml cartridges). According to Yuko Maeda, Roland DG division president of digital printing, market development, the larger size not only accommodates less ink cartridge replacements, but is more economical.

On InkTec’s cards…

With 25% of the InkTec workforce involved in dedicated R&D, InkTec strives to remain at the forefront of the latest print technologies. And with the growing trend in textile print, the firm has unleashed its Sublinova ink, specifically for textile printers using the popular Ricoh printhead. And recognising the broadening variety of media that printers are now requiring to use, InkTec has also developed ink with an in-built primer specifically for its Jetrix.

Looking at facts and figures on consumption across the various ink/printer types, InkTec says the realities are that ink consumption varies dramatically not only from brand to brand but also from device to device. Most UV flatbeds will consume less ink than traditional roll fed solvent machines and with the Jetrix KX range, ink consumption is as low as 5ml/m2 even at 100% ink coverage. In comparison, InkTec UK sales manager Ben Woodruff asserts, an Epson SureColor S30600 running eco-solvent inks, uses around 21.24ml/m2 at only 90% ink coverage.

“Not all vendors are open with the information relating to ink usage,” says Woodruff, “so it’s wise to ask the question prior to making a purchase. Ink consumption can also be increased or decreased by using a good ICC profile with the correct ink limits. Some generic profiles will over-saturate ink, which results in a needless waste of money.”

Like everything technology based, the practicalities of keeping up with technology mean that machines are being developed faster, with current models becoming obsolete much quicker than in the past. Newer models quickly supersede them, so you could argue that ink prices are unlikely to drop in the future, as more time and money is spent on R&D!

Sunjet unlocks new sectors…

“Rapid advances in inkjet print technology continue to open up new sectors for wide-format printers,” explains, Sunjet global business director Peter Saunders, “and with confidence in quality and performance at an all-time high, these printers are enthusiastically embracing

inkjet as the way forward. With this continued growth comes a demand for new inks that will not just provide quality colour reproduction but also address environmental concerns, delivering across a range of new substrates and increasing efficiencies in production.”

“At SunJet, we don’t just monitor the market,” Saunders points out, “we anticipate future demands and look to develop ink solutions that will enable customers to take their businesses forward. In terms of future ink developments, in addition to our UV solutions, we are also looking to how aqueous based chemistry can widen the scope of materials and markets with our new breakthrough, functional, water-based Aquacure inkjet technology. Aquacure will have a real significant impact on inkjet applications, both in the well established and emerging inkjet market segments.”

Aquacure, with its extensive colour gamut, flexibility and strong adhesion to a wide range of substrates is heralded as a game changer by Sun: aqueous ink for wide-format digital with true functionality. This ink, developed for consumer and environmental acceptance is a very low odour, sustainable solution that provides an improved hazard profile. “This innovative chemistry is a platform which looks to the future,” says Saunders.

Aquacure brings significant advantages for graphics but is not limited to this sector as it can achieve migration limits and compliance for primary food packaging, in combination with appropriate press design. The ink also boasts a good health and safety and environmental profile, delivering significant hazard reduction in labelling compared to current solvent and UV chemistry.

On another tack, eco-solvent inks, Sun Chemical is extending its new low odour chemistry with the introduction of ESL 2 series, fully colour matched for the latest Roland Pro4 generation of eco-solvent printers. Sun says it provides a direct alternative to Roland’s Eco Sol Max II inks for use in Roland’s Pro 4 XF 640, XR 640, Versa Express RF 640 and VersaCamm VSi eco-solvent wide-format printers. Sun will continue to provide ESL HPQ LO ink for those using Roland's Pro 2 and Pro 3 platforms. Streamline ESL 2, based on high print quality, low odour chemistry, comes in seven colours with a revised nickel-free yellow, light cyan, light magenta and light black.

Sun Chemical product manager James Gould says: “The inks have gone through stringent tests, both in-house and at beta customer sites across Europe, to ensure a robust ink formulation that can deliver the highest standards across multiple print settings and substrate types. Results have also shown that ESL 2 offers excellent outdoor durability." ESL 2 comes in 440ml cartridges and 1litre bottles and can be used in Sun Chemical's Streamline bulk ink systems.

Bear in mind…

JK Group

Sawgrass Industrial, maker of sublimation and water-based pigment inks, is joining other digital ink specialists Kiian Digital and J-Teck3 as part of the JK Group. Sawgrass Technologies will continue to operate as an independent company serving the needs of digital printing applications on printers less than 42in addressing non-industrial customer needs.

Sawgrass founder and CEO Nathan Hale said of the move: “Now that digital mass production is a reality for printing onto textiles, this is a perfect time to form a strong alliance to deliver on what was just a dream.”

JK Group president, Dennis Wilby, said: “Following the combination of Kiian Digital and J-Teck3 last year, the addition of Sawgrass Industrial takes the JK Group into a global leadership position in the digital sublimation sector and at the forefront of the textile pigment inks market development.” CEO Alberto De Matthaeis, added: “We believe that the synergies of working together will add significant value to the three brands while retaining their independence with separate sales, customer service and product development.”

Bordeaux

Bordeaux has made a strategic commitment to broaden ink solution options, and to offer new solutions for both the fashion and soft signage industries. Fespa marked the launch of the company’s Velvet Jet division, dedicated to digital textile printing solutions. Since then we’ve seen partnerships with the likes of Ultimatum Engineering, that means the latter will offer the Bordeaux UV and UV LED ink ranges for the Oce Arizona and Fujifilm Acuity printers.

{jathumbnail off}