With blockchain, invoices can be settled almost instantaneously. Interested? Walter Hale explains the technology that has everyone talking.

Technical

Mission: control

What are the latest developments that can help large-format PSPs streamline their workflow to create a more profitable business? Richard Stuart-Turner investigates.

Christoph Gamper, CEO, Durst

As Durst celebrates its 70th year Lesley Simpson asked CEO Christoph Gamper about the company’s future direction and its commitment to large-format inkjet.

Clouded judgement

Walter Hale investigates Cloud computing and its relevance to large-format print SMEs.

Duncan Ferguson Executive director, professional printing and robotics, Epson

In this new series of features with key large-format kit and consumables manufacturers, Lesley Simpson asks how large-format inkjet will be positioned within Epson as it focuses on new technologies and markets.

Inkjet at the commercial crossroads

As we reflect on another inkjet dominated Drupa, Richard Stuart-Turner asks ‘what are the implications of industry-wide developments for the large-format print service provider?’

Now screening...

Walter Hale looks at digital signage and asks whether this blockbuster technology is something you need to be paying more attention to?

In the pink

Very healthy R&D budgets leading to significant innovations in ink. Simon Creasy reports.

Put your hands together

In a special ceremony at Drupa, the European Digital Press Association (EDP) - of which Image Reports is the UK member publication - presented its annual awards. Here’s the low-down on the winners and runners-up.

Eyeing up wearable technology

Walter Hale considers developments in what has so far been seen as a faddish sector, and looks at how it could impact upon your business.

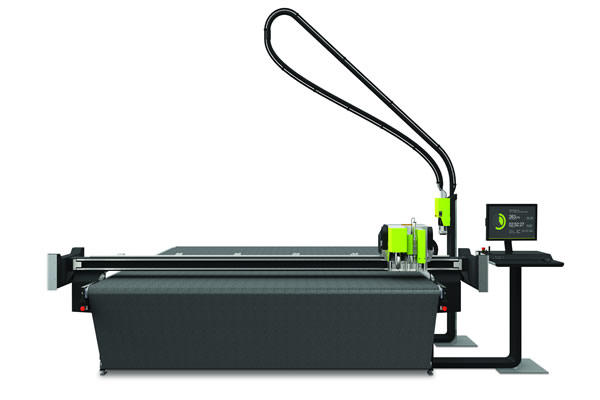

Cut it out

Are you still arguing over whether to buy a router or cutting table? Nessan Cleary helps solve your dilemma.

ON TEST: Mimaki JFX200

Mimaki’s entry-level flatbed has proven popular since it was first launched. Nessan Cleary check’s it out to see why.

Print 4.0: the substance behind the hype

Is intelligent networking really within our ken? Walter Hale explores the possibilities.

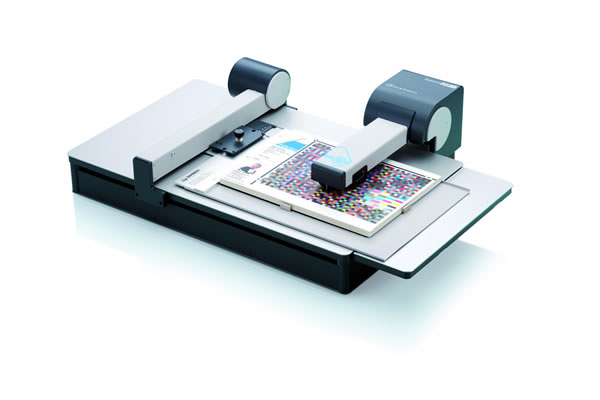

Chasing consistent colour

The key to getting good, repeatable results from any digital printer lies in the quality of the profiles that you use with it as Nessan Cleary reports.