By Rob Brown, Head of Graphic Arts & Industry Print, UK, Ireland & Nordics

Most organisations across the creative, graphics arts and print sectors are looking for ways to differentiate; to find new revenue streams and ultimately to expand their business. At the same time, however, they are also wrestling with a raft of challenges. Many are experiencing increased demand for unprofitable short runs; others are outsourcing specialised processes that chip away at their profits or are alternatively having difficulty with a specific area of the work: printing on heavy media, for example.

A much smaller group appreciate that the latest print devices, from wide format through to light production, envelope printing and transfer media, offer them a means of addressing their challenges and achieving their end goals. The truth is that these kinds of printers typically offer these businesses an excellent means of generating income quickly and cost-effectively and therefore driving a fast return on investment (ROI).

In a recent survey of print businesses, Widthwise 2017, carried out by Image Reports, 43% said wide format profit margins were better than any other part of their business while 88% said that ten years from now they still expect to be in wide format printing. The potential for the transfer media printing market looks great also, with 70% of respondents to a recent FESPA global census saying they expected personalisation printing to increase.

Its worth remembering that it is not the traditional speeds and feeds and printer specifications in general that are important here. Simply by using what’s in the box itself, many businesses will be able to expand their range. If you are in the business of selling merchandise, for example, the latest white toner printers may be able to deliver enough free toner to print thousands of t-shirts, and therefore tap into significant revenue-generating opportunities. If you are a small sign company, the ability to create high-quality signs and labels quickly and easily can be crucial in keeping existing customers happy and tapping into new markets.

Beyond this, printers also often provide businesses with the opportunity to expand into new application areas. The latest machines might, for example, enable you to move from just printing indoor banners to additionally offering customers a new outdoor banner range. Moreover, cutting edge graphic arts printers could enable you to start printing eye-catching designs onto thicker stocks, textiles or textured papers. It’s all about opening new routes to market and enabling businesses to grow.

Delivering Solutions across a Range of Sectors

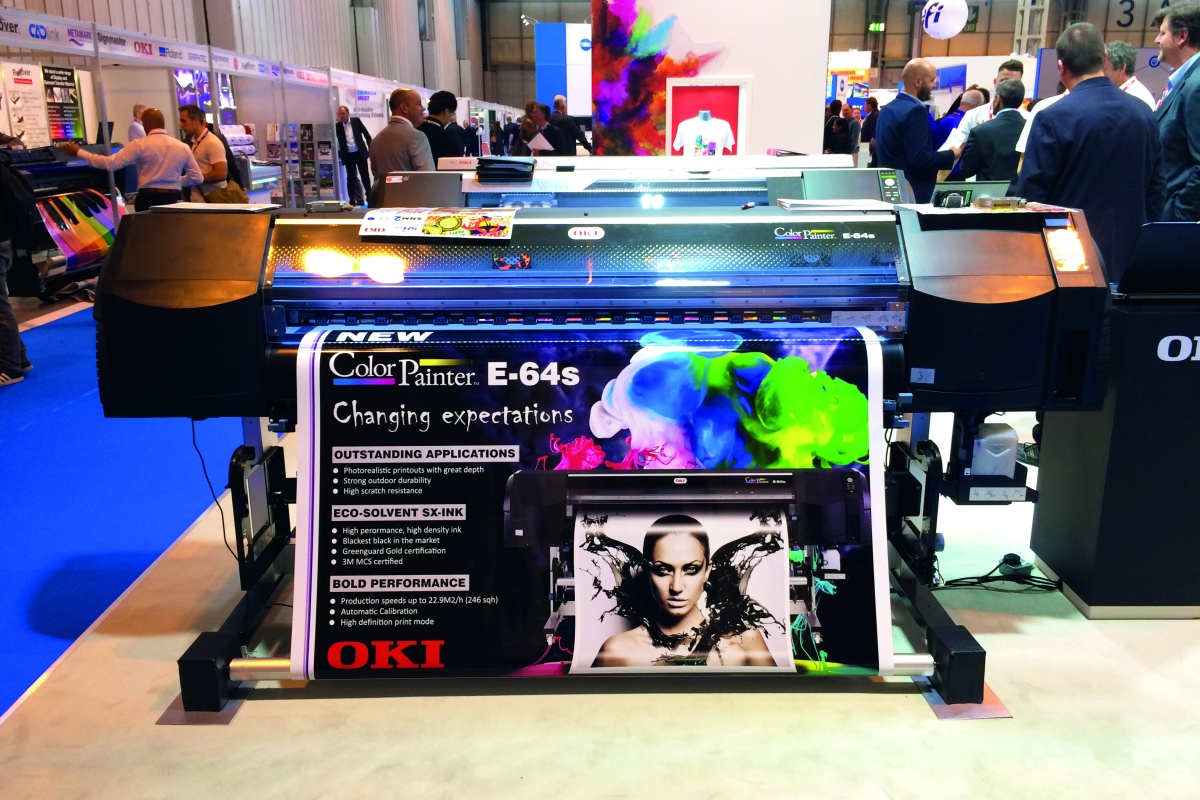

Of course, the latest graphics arts solutions can be key in delivering solutions across a range of different areas. In the large format print arena, the focus is on delivering brilliant colour and high durability solutions for indoor and outdoor applications, helping businesses across the graphics communications industry to print wide print in-house in rich glossy colour and sharp detail.

At OKI, we concentrate on delivering easy to use high-performance solutions, with entry level, medium and high-volume printer options available capable of generating high-quality indoor printing and durable guaranteed long-life outdoor applications. Through OKI printers, end customers can print on a wide variety of substrates including wallpaper, fleece, canvas and other textiles. They can print quickly, and consistently, giving them the peace of mind that comes from knowing colour will be distributed consistently and that the ink will be low-odour.

The ability to enter into the outdoor sign market can be critically important for many graphics arts and print-based businesses, in opening lucrative new market areas including retail signage, building hoarding and wraps and key growth areas like window graphics; exhibition display panels and vehicle signage and wraps. That’s another key benefit that the latest large format printers can deliver.

Of course, some businesses might be deterred from taking the plunge initially due to what they perceive to be the high entry costs to the wide format market. This is likely to be a false economy. Say, they are selling banners at £30 a week and they make a hardware finance payment of £50 per week on their device, then they will only need to sell two banners a week to effectively pay for it.

The challenges facing businesses operating in the transfer media printing market are also making the choice of printing device increasingly important. Transfer media printing involves printing a high-resolution image on to quality transfer paper. The image on the transfer paper is then applied to the finished product or clothing using a heat press.

The growth and development of transfer media printing is being driven by the need for shorter print runs, variable and personalised content and ever-higher output quality. The advent of this kind of printing means that print shops no longer have to immerse themselves in set-up times and messiness of screen printing. Instead, they can reap the rewards of hardware and ink costs that are markedly lower than rival direct-to-garment technology, that take up less room and require no extra equipment for pre-treatment or drying. Transfer media printing is also more reliable and easier to use than thermal heat transfer.

As the market leader in white toner digital printing, OKI plays a key role in this marketplace. Previously, printing in white was an expensive, time-consuming task often only handled by larger print houses. However, OKI’s white toner printers remove this last barrier to creativity. Now graphics businesses can print in any colour, including white, on a range of media, simply and cost-effectively in-house. OKI also offers a neon colour printer that incorporates a unique black or white quick swap print cartridge feature, making it easy to bring printed documents, packaging or educational materials to life with dazzling, luminescent colour on either dark or light backgrounds, and drive new revenue-generating opportunities into the bargain.

Finally, businesses that adopt light production printing (LPP) give themselves the opportunity to create stunning, innovative added value options for their clients. OKI has a range of graphics arts solutions for light production that are just right for short run digital printing that can be reprinted on demand. From flyers, brochures, leaflets, newsletters and proof-of-concept packaging, to technical manuals and annual reports, versioning and pre- and post-production printing is cost-effective removing the need to produce large volumes unnecessarily, thereby avoiding waste.

With a growth in demand for highly targeted, creative direct mail, OKI’s Graphic arts solutions can meet the requirement by creating customised printed versions based on criteria such as geography, language and demographics, offering the flexibility to test promotions and produce pre- and post-print runs in an economic way. Print services providers can also employ customer data and digital printing to produce personalised customer mail for more targeted marketing using variable data printing. This generates higher margins per printed page and can lead to a significant boost in revenue.

What’s in the Box

So, for any graphics arts business looking to branch out and take advantage of opportunities to grow their business, its worth considering that the solution to the challenges in driving expansion may be sitting in front of them in the shape of their printing device. It’s not the box itself or its precise specifications, or ‘speeds and feeds’, that matters here, of course, it’s what comes out of the box, the opportunity to expand into new market areas and start generating incremental revenue streams that really matters to the end customer. And that’s precisely what the latest graphics art devices from OKI can help deliver for them.