Using UV-curable inks has become the de facto way of bringing versatility into the overall productivity of wide-format print houses, display producers and sign-makers. However, there’s now an additional way to add to the investment benefitsof a new printer in the form of LED curing that brings extra flexibility, lower running costs and results in a greener working environment.

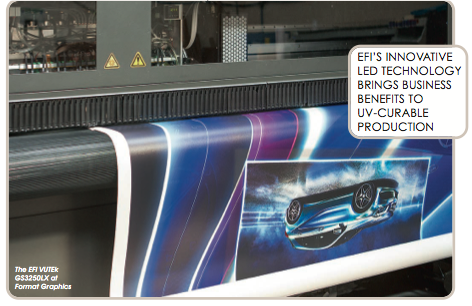

As today’s machines have evolved from the engines that were first recognised as being the road to profitability for businesses, so EFI has gone one step further, acknowledging the need for more environmentally aware opportunities by integrating its ‘cool cure’ technology into its VUTEk GS3250LX and GS2000LX platforms.

As today’s machines have evolved from the engines that were first recognised as being the road to profitability for businesses, so EFI has gone one step further, acknowledging the need for more environmentally aware opportunities by integrating its ‘cool cure’ technology into its VUTEk GS3250LX and GS2000LX platforms.

With the emphasis on efficiency and lowering the total cost of ownership across the printer’s lifetime, EFI’s cool curing technology enables users to produce jobs far more efficiently at higher speeds and with superior quality. The VUTEk GS3250LX and GS2000LX are able to reduce operating costs by using lower power consumption while increasing uptime, with the LED curing lamps offering instant on/off, long life and consistent performance.

The cool curing capabilities of the LEDs mean that a vast range of rigid and flexible materials is supported, and now it’s simple to print direct to media which formerly was not possible using conventional UV-curable ink technology. The very low temperatures generated by the lamps eliminate buckling and warping of the substrate, and even the thinnest and most sensitive of films can be used without fear of head crashes or heat damage.

This increased guarantee of reliability is complemented by the greener credentials of the VUTEk GS3250LX and GS2000LX which emit no VOCs and generate lower waste. The printers’ ability to be used with recycled materials adds to the overall benefits of a more sustainable work-flow and eco-aware results. Its consistent colour accuracy and high standards of performance are complemented by EFI’s innovative ink technology that provides excellent adhesion across all surfaces, even when curing at low temperatures.

The first in the UK

Format Graphics is a prime example of a company which opted to take the LED curing route and make it an integral part of its business’s motivation for greater productivity and increased flexibility. This installation was the first VUTEk GS3250LX 3.2m flat-bed and roll-fed system with LED technology to be installed in the UK.

Formed by Baz Ogle in March 2013, Format Graphics concentrates on producing a broad portfolio of high quality wide-format applications for a diverse customer list. Working primarily with designers and agencies with blue chip clients, fine standards of print with accurate colours are vital to meet the exacting criteria required by end customers, many of them major brand owners.

Ogle has been a long time user of VUTEk platforms, starting with an early PressVu 200-600; followed more recently by QS and GS machines, it was a straightforward decision to continue with EFI technology. Although he originally considered the VUTEk QS3 Pro, Ogle changed his mind when he discovered more about the opportunities available and the overall benefits of the GS3250LX. “The idea of EFI’s cool cure technology appealed to me greatly, and it was easy to assess the advantages of LED curing with the diverse variety of materials we use at Format Graphics,” he states. “The ability to print direct even to the most difficult media without compromising on either speed or quality made me decide that the VUTEk GS3250LX was the machine we needed. Buying this wide-format printer also meant we could become more environmentally responsible through using a greener technology and reducing our power consumption.”

No alternative to VUTEK

Ogle looked at wide-format printers from other manufacturers but decided there was no alternative to the VUTEk which was the only printer to give him all the production and quality capabilities he needed, plus all the advantages of LED curing. Of particular importance was the fact that the GS3250LX has a full 3.2m width for both rigid and roll materials, plus the capability to print continuous boards, a feature no other printer in the same class was able to provide.

Format Graphics also required a true hybrid printer with quick change-over from rigid to flexible materials and back again. Ogle explains that currently the company’s throughput is split evenly between flat-bed and roll-fed work, and the capabilities of the GS3250LX along with its LED curing have proved to be ideal for handling sensitive media which reacts badly to heat.

The environmental benefits of the VUTEK GS3250LX were another key benefit for Format Graphics. “These days many of our clients want to work with suppliers that offer greener productivity,” continues Ogle. “Using UV-curable inks with LED lamps means that there are no emissions, such as ozone or VOCs, and our energy requirements are lower.”

Dan Preston, a very experienced VUTEk operator who joined Format Graphics at the outset, is finding the GS3250LX is a joy to use. “As well as the advantages we’re finding with the LED curing, this printer gives us stronger, more vibrant colours across all materials,” he says. “We use a lot of white ink, and the opacity on this machine is particularly good.”

“Having a printer which is kinder to vinyl and other difficult materials has extended our range of applications as we can print direct to media that might not be suitable for use with mercury arc curing lamps,” states Ogle. “We also don’t get any ruined jobs. There’s nothing more disheartening that finding a surface that should print perfectly has been damaged beyond use at the curing stage because of the high levels of heat that have been emitted. Knowing that applications won’t buckle or warp, and eliminating the possibility of head crashes, is a tremendous advantage.”

Speed and reliability

The speed of throughput has also impressed both Ogle and Preston who are using the latest version of EFI’s Fiery XF RIP. Able to run the machine at 90 square m/hour means that a 2.4 x 1.2m (8 x 4ft) board prints in less than three minutes. Additionally, experience with VUTEk for many years has shown the machines to be extremely reliable and hard-working, both essential prerequisites for Format Graphics.

The speed of throughput has also impressed both Ogle and Preston who are using the latest version of EFI’s Fiery XF RIP. Able to run the machine at 90 square m/hour means that a 2.4 x 1.2m (8 x 4ft) board prints in less than three minutes. Additionally, experience with VUTEk for many years has shown the machines to be extremely reliable and hard-working, both essential prerequisites for Format Graphics.

EFI’s cool curing technology has quickly confirmed that using LEDs instead of conventional lamps is proving itself from both a business and economic standpoint. Users continue to be amazed at some of the unusual materials that can be printed and the extended range of applications that can be offered to clients. The superior output quality can be extended even further with the greyscale option in the Pro model of the VUTEk GS3250LX and GS2000LX, reducing ink usage and perfecting the production of the finest detail and graduated tints.

Since EFI first launched the VUTEk GS3250LX in 2011 it has steadily gained momentum worldwide for the versatility available with its innovative LED curing technology plus JDF connectivity and seamless integration to EFI’s web-to-print and MIS solutions. Proving to the be ideal solution for businesses wanting to extend their production capabilities, this printer series has quickly gained a reputation for lowering total cost of ownership and increasing greener working practices.

Find out more about how EFI's cool curing can transform your business.

Contact:

Simon Casajuana

Tel. 07887 842786

Wesley Small

Tel. 0773 0841 114

{jathumbnail off}