Some 75 years after the father and founder of the Jet Engine, Sir Frank Whittle, formed his Power Jets Ltd. company in Lutterworth - another company is taking-off with its business. Working out of the same building where the foundation block of the jet aviation industry was born, Pure Point of Sale Ltd. has seen its sales and growth soar in its first five years.

It all started for Pure in 2009 when two long term friends, Russell Murch and Liam Gibbs, Managing Director and Sales Director respectively, decided their backgrounds and industry contacts would be a great basis for a print and POS business. Like Sir Frank Whittle, the partners started from humble beginnings - purchasing a Roland digital printer from eBay and running the business from a conservatory. Just five years on and Pure has premises boasting 20,000 sq ft, employs 20 staff and anticipates a turnover of £1.5m in the next 12 months.

This success comes from a partnership that combines Mr Murch’s extensive background in the print production industry and Mr Gibbs’ experience as a retail designer specialising in POS/POP fixtures and fittings with the likes of Tesco, Homebase, and George - the clothing subsidiary of the Wall-Mart (Asda) Group. After Mr Gibbs moved on from working at George to his current position, Pure quickly became a trusted supplier for the retail giant. Pure now supplies all of George’s 400+ UK outlets as well as many of the company’s international franchise partners.

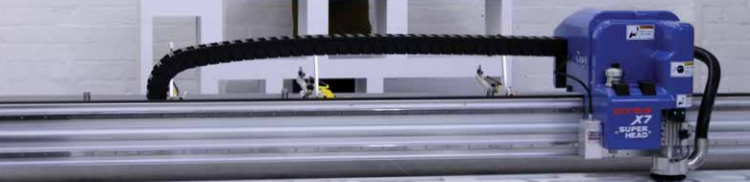

To accommodate the continuous growth, Pure has invested heavily in staff and state of the art equipment. The latest acquisition being a DYSS X7-3216 Digital Cutter from AG/CAD that arrived at the end of October.

Why buy a digital cutter?

For Pure, the selection of the DYSS was initially made out of necessity. The company is growing year-on-year and it needed a high-speed cutting machine to underpin its growth. The Lutterworth company already had an KM626A cutting table from AG/CAD but it was struggling to keep up with increased production demands. The machine also only had the capacity for knife cutting which limited the range of C materials that could be processed. In the early days of the business, knife cutting and creasing cardboard freestanding display units (FSDUs), in-store POS and window displays meant this machine was sufficient. However, as the company has grown and invested in superwide digital print equipment, it has expanded the product ranges it handles for its blue chip clients and this has created a requirement for increased capacity and the ability to process more varied substrates.

As Mr Gibbs comments: “As our reputation for quality POS products has become more established, our customers are entrusting us with a more diverse workload that is now reaching into the design and production of semi-permanent and permanent POS displays. Historically we’ve cut cardboard, thin Foamex (rigid PVC) and displayboard, but as we have moved into the semi and permanent display sector, we are cutting DIBOND, Acrylic, wood, aluminium and thick Foamex up to 20mm thick. A knife cutting machine was never going to cut these tougher materials, so we wanted a digital production cutter with the option of a high powered routing tool as well as knife and creasing tools. For some time, these jobs have been subcontracted out to suppliers; buying the DYSS has eliminated this reliance on external sources.”

Why choose Dyss?

The decision to opt for the DYSS cutting machine was manyfold. Firstly, Pure already had a cutting table from AG/CAD and the reliability and service has been excellent. Mr Murch takes up the story: “The existing AG/CAD table has been remarkably well supported in the four years that we’ve had it and this is always a key factor for any manufacturing facility. We’ve developed a great relationship with AG/CAD and we’ve been impressed with the cutter, but now our requirements have outstripped its capabilities. Another factor in our selection process was the KASEMAKE CAD software from AG/CAD. We’ve been using the software for four years and it’s been an exceptional design and sales tool for us.”

Despite AG/CAD already wowing the company with its reliability, service and KASEMAKE software, it was by no means a ‘done deal’. As Mr Murch recalls: “We had to investigate the market for alternative options and we looked at all the leading suppliers. However, the superwide format, high quality and robust build, powerful cutting tools, impressive cutting speeds and the upgraded KASEMAKE software really did seal the deal. Not only that, but AG/CAD also listened to our requirements and adapted the DYSS to suit our specific needs. No other manufacturer was willing or able to do this.”

What advantages has the Dyss brought to pure point of sale?

As Pure has grown, so has its plant list and this also includes a two year old EFI VUTEk QS3200 printer with a 3.2m width flatbed and roll to roll capability. Printing up to 3.2m wide caused a cutting issue for Pure, as it couldn’t fit 3.2m width jobs on its original cutting table. By installing a DYSS X7 flatbed digital cutter with a 3.2m wide by 1.6m cutting capacity along with a rear sheet feeder and roll unwinder, a production flow has been created whereby large print jobs can be transferred straight from the VUTEk to the DYSS. With a plant list that will shortly include a HP Scitex FB7600 printer with a 3.2m by 1.6m flatbed, the DYSS will comfortably accommodate the output from both machines. At Pure’s request AG/CAD also customised the rear sheet feeder to allow 3 sheets of board to be loaded and processed at once for optimum productivity.

On top of improving the through-flow of work, the DYSS has been able to reduce the lead-times for prototypes, design development and small batch jobs. As Mr Gibbs continues: “Prior to the arrival of the DYSS, any prototype jobs that were required from acrylic, DIBOND, thick Foamex, and other tough materials would take up to 3 days to turnaround because we relied on external suppliers to cut the jobs. Now, we can do all this internally, reducing our lead-times from 3-4 days to just 24 hours. Additionally, we now use the DYSS for small POS production runs that we previously had to use our die cutter for. This would entail having die formes produced externally at a cost and lead-time that would hinder our turnaround times and disrupt the through-flow of our work schedules.”

What are the cost benefits with the Dyss?

The remarkable power and cutting speed of the new DYSS X7 enables Pure to process small production runs of up to a few  hundred on the machine cost effectively without sourcing dieformes and stamping out jobs on a traditional die-cutter. As Mr Gibbs enthuses: “At a cost of £150-£200+ for a die-forme, the monthly cost would vary depending upon workload. As a conservative estimate, we would spend upwards of £1,500 each month on die-formes. This has now been cut by at least £1,000 a month thanks to the DYSS.In addition, we don’t have the associated lead-time issues with sourcing dieformes. With some existing jobs where we already have formes, we will continue to use these, but all new jobs go on the DYSS.”

hundred on the machine cost effectively without sourcing dieformes and stamping out jobs on a traditional die-cutter. As Mr Gibbs enthuses: “At a cost of £150-£200+ for a die-forme, the monthly cost would vary depending upon workload. As a conservative estimate, we would spend upwards of £1,500 each month on die-formes. This has now been cut by at least £1,000 a month thanks to the DYSS.In addition, we don’t have the associated lead-time issues with sourcing dieformes. With some existing jobs where we already have formes, we will continue to use these, but all new jobs go on the DYSS.”

In addition to reducing overheads by cutting its reliance on die-forme suppliers, Pure has also slashed the cost of externally cut DIBOND, acrylic and thick foamex jobs. The new DYSS X7 cutting machine has reduced the ISO:9001 and ISO:14001 accredited manufacturer’s reliance on external subcontractors to cut all materials beyond the limits of its old cutting table and now gives them full in-house quality control. As Mr Gibbs continues: “We got to the point where we would be spending upwards of £20,000 a year on externally cut jobs. This cost has been completely eliminated by bringing the work in-house and cutting on the DYSS X7.”

“Despite only being installed a few weeks, we can already see the huge cost benefits of installing the DYSS, whilst the ability to bring more work in-house has improved our leadtimes, process reliability and workflow. We are delighted with the benefits the X7 machine has brought in a few short weeks and undoubtedly we’ll continue to benefit immensely as time progresses” concludes Mr Gibbs.