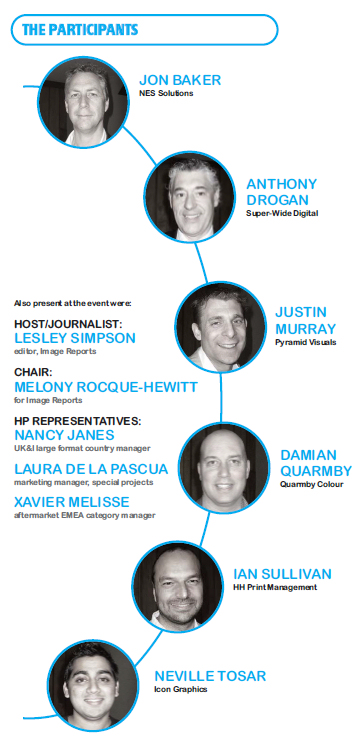

What’s the real dynamic between printer and supplier? Is it the business partnership we’re told it should be? We asked printers from a cross section of the industry, Jon Baker from NES Solutions, Anthony Drogan from Super-Wide Digital, Justin Murray from Pyramid Visuals, Damian Quarmby from Quarmby Colour, Ian Sullivan from HH Print Management and Neville Tosar from Icon Graphics, for their experiences and views...

The printer/supplier relationship has often been an uneasy one but it has nevertheless developed into one of mutual respect where both parties now interact more closely in business partnership for the good of their own operations and for the sector as a whole. Discuss.

It’s OK - the intention isn’t to give you recurring nightmares of your exam days, but to open the debate on the oft proffered argument that today, manufacturers and suppliers are much more than sales organisations – that they are business partners ready to help you develop your potential. It’s a message of hope that gathered momentum throughout the recession and which is carrying over into the current exhibition season. There’s little doubt that at a strategic level many suppliers have shifted focus when it comes to the way in which they engage with their (potential) customers and understand that a more symbiotic approach to business development will help future growth. But how’s that panning out at grass roots level? We asked a group of players in the wide-format print market to discuss their experiences and give their suggestions on how the relationship with suppliers could be improved.

Given that print service providers are increasingly selling ‘solutions’ rather than print, the panellists were first asked how they felt manufacturers were adapting to this and helping them move on. Ian Sullivan of HH Print Management hit the nail on the head with the comment: “Marketers are constantly pressuring the market for new ideas and so printers need to put pressure on the manufacturers and suppliers to help them find new solutions. What might really help would be if suppliers had a ‘champion’ who was proactive and whose job it was to talk to printers and ask ‘anything we can help with?’” As to what sort of help that might be covered a swathe of options, but the general feeling was that suppliers are still not offering enough after sales support, whether that’s technical or business focussed. “When they initially try to sell you a machine they say they will help you in developing your business but that’s not really followed through once you’ve bought that machine,” said Neville Tosar of Icon Graphics. “No, I really don’t see any active participation in business development,” added Anthony Drogan from Super-Wide Digital.

Given that print service providers are increasingly selling ‘solutions’ rather than print, the panellists were first asked how they felt manufacturers were adapting to this and helping them move on. Ian Sullivan of HH Print Management hit the nail on the head with the comment: “Marketers are constantly pressuring the market for new ideas and so printers need to put pressure on the manufacturers and suppliers to help them find new solutions. What might really help would be if suppliers had a ‘champion’ who was proactive and whose job it was to talk to printers and ask ‘anything we can help with?’” As to what sort of help that might be covered a swathe of options, but the general feeling was that suppliers are still not offering enough after sales support, whether that’s technical or business focussed. “When they initially try to sell you a machine they say they will help you in developing your business but that’s not really followed through once you’ve bought that machine,” said Neville Tosar of Icon Graphics. “No, I really don’t see any active participation in business development,” added Anthony Drogan from Super-Wide Digital.

But not everyone felt that way. “We are entering new markets and we find the suppliers do try and help us – but they also follow us,” said John Baker of NES Solutions. “It is important that you do your own research into new solutions and see what you can do inhouse, but we do talk to suppliers and we find some are helpful and others aren’t.”

“Yes, we have to be experimental and see what we can do for ourselves, but there are suppliers recognising that we need to offer something different and providing new solutions accordingly – take the HP latex ink printers and Zund cutting tools – they’ve opened up new areas of business for us,” enthused Damian Quarmby, Quarmby Colour.

The relationship between printer manufacturer and substrates suppliers came under the spotlight, with many around the table feeling that a closer relationship there would help printers provide more applications with less hassle. “You go to an exhibition or whatever and you see printers that can work with all sorts of substrates etc. But once you get the machine in-house you find you have to devote lots of internal research time to profiling and tweaking this and that to see what works in a live environment,” said Murray, echoed by Drogan: “There must be loads of printers all testing various substrates and profiles on certain printers in-house. Rather than all that being duplicated all over the place, why don’t the suppliers collect the information and put it somewhere centrally where other users can get at it more easily. We understand that the suppliers themselves can’t test every substrate on every printer, but somewhere, somebody is probably trying them.”

The relationship between printer manufacturer and substrates suppliers came under the spotlight, with many around the table feeling that a closer relationship there would help printers provide more applications with less hassle. “You go to an exhibition or whatever and you see printers that can work with all sorts of substrates etc. But once you get the machine in-house you find you have to devote lots of internal research time to profiling and tweaking this and that to see what works in a live environment,” said Murray, echoed by Drogan: “There must be loads of printers all testing various substrates and profiles on certain printers in-house. Rather than all that being duplicated all over the place, why don’t the suppliers collect the information and put it somewhere centrally where other users can get at it more easily. We understand that the suppliers themselves can’t test every substrate on every printer, but somewhere, somebody is probably trying them.”

Given that we’re now in exhibition season, the question of whether product introductions are too speedily brought to market was a timely one, and Murray spoke for many when he said: “Everybody now expects a machine to come to market when it’s not really ready, especially when there’s a big show. We know that if we’re one of the first to buy a newly introduced printer that it will take six months before it’s fully operational.”

“I think we’d all like to see more honesty from suppliers. Saying ‘we’re nearly there, we’re working on it’ is better than delivering something that isn’t quite ready. If a supplier took that approach I think that in the longer term they would gain more trust from the print community,” Quarmby said, to vigorous nods of assent from the other participants. “I bought a machine that I was told could print ten feet boards only to find out that it couldn’t. I told the supplier who said they would have to rewrite the software and it took nine months to get it printing at the width specified in the sales literature,” highlighted Drogan.

This moved the debate on to the contentious issue of postinstallation software updates. “It’s diabolical that you have to pay for software upgrades because you’re an early adopter,” argued Sullivan, “when six months down the line other purchasers effectively get them for free.” He also pointed to a need for suppliers to work more closely among themselves on areas such as workflow: “We buy various pieces of kit and expect it to bolt together in terms of workflow etc. – we need suppliers to think outside the box a bit and work in closer co-operation.”

The speed at which new kit is brought to market particularly ruffled Baker. “We shouldn’t need to reinvest in printers every couple of years. Suppliers should be working more closely with us trying to find new ways of doing more with the kit we’ve got by developing news inks, software, substrates etc.”

When it came to the question of machine maintenance and warranty the supplier/printer relationship came in for something of a battering, with comments such as “we need warranties so suppliers hold you to ransom”. “A ‘no claims’ discount scheme should be instigated, whereby if operators look after their kit you get a reduced, tiered rate,” said Quarmby.

Some of the panel had pulled out of warranty schemes before renegotiating their cost, others said they duck in and out of warranty contracts depending on when they feel they are going to be most beneficial (ie when they realise a printer is going to need new heads) while others have opted for alternatives. “We have an insurance policy with RBS which covers all our machines and is a lot cheaper,” said Baker. A popular move is handling any problem inhouse: “We keep one of our decommissioned printers in the back and just use it for spares,” said Murray. Others around the table said they do likewise, citing “the inflated cost of new parts”.

“It’s not just about cost, it’s the fact that even with warranties you can wait for days for someone to turn up and fix the problem. If suppliers really want to partner us in business simply making sure kit keeps running would help,” said Sullivan. “What we really need is some sort of organisation that printers can turn to discuss specific kit/supplier problems – which over time would throw up trends - and who can then put pressure on the relevant companies.”

Could better operator training by suppliers both improve the uptime of the print kit, and improve the service offering of the print service provider? The question brought the nigh on unanimous comment that basic operator training is, well, too basic! “Some suppliers already offer different levels of operator training, but not all, and it can be very costly,” said Murray. “What doesn’t help is that sometimes the trainers are actually engineers, who may know the machine very well, but miss the nuances of how it will work in a real print environment. It would help if they themselves spent a week with the machine in a print environment and got to understand issues like workflow – they are too ‘clinical’.”

“Actually, we’ve found that because we’ve been putting live jobs through the printer with trainers on site, they have helped us out enormously,” said Quarmby. “And I’ve actually come back from supplier-led training sessions overseas with new ideas because I’ve been shown the full capability of the machine I’ve bought.”

“That is a good point – on the whole training isn’t applications focussed at all, it’s very basic running, cleaning, maintenance information from what I’ve seen,” added Drogan. “Stepped training over a period of time, done in-situ and at the higher level with an applications focus would be ideal.” With the discussion turning to new applications, the panel was asked about the suppliers’ role in helping printers differentiate their offering. “We haven’t really talked to suppliers about new/growth markets,” said Tosar, with Quarmby quickly following with: “We’ve never had any hints or tips from a supplier about expanding or diversifying into new markets. The focus has been increased speed, quality and reliability of machines. We’ve taken it on ourselves to expand into new markets.”

“How much do suppliers really know about emerging markets anyway – can they really give us valuable information?” asked a cynical Murray. Drogan’s rejoinder was: “The thing is, suppliers may not have ‘market’ information but they know the capabilities of their machines very well and it’s surely in their long term interest, as it is in ours, to help new markets develop by gathering as much data as possible and sharing it.”

“The problem is that suppliers face competitive edge issues when trying to provide case studies etc. in specific areas, so really it is going to fall to the printer to find and educate the market about the possibilities,” said Sullivan. “Unless you have a need or want from a client that’s where it all falls down. 90 – 95% of our business is client driven and we have to follow them. You can look at lots of potential offerings but if the majority of clients don’t want them you have to ask whether it’s worth the effort. Building a new client base takes a lot of time and money,” a comment eliciting hot debate about the cost, requisite management and sales skills, and strategic planning capabilities of print companies to expand the boundaries. “Yes, you need customer churn but if we were reliant on repeat business we’d be in trouble,” argued Baker. “If you’re not inviting interest in new markets where is your business going to be in five years when somebody else steps in and offers what you’re offering now, only cheaper. Building new markets has its risks but they are ones we have to take.”

In response Sullivan made the point that perhaps, given the level of commitment needed to be successful in a new market, it makes the greatest sense for new applications to be developed in-house, giving the printer an inherent confidence in the concept/product, rather that running off the back of what a supplier may say can be achieved. “New applications will eventually trickle down in the market, but if you don’t hit the right trend at the right time it’s a waste of time,” he said.

And what about the suppliers selling machines to one-man startups – how does that impact on the business partnership argument? Perhaps surprisingly, those on the panel had no problem with this. “It’s an open market so I don’t think it’s fair to criticise manufacturers for doing this,” said Murray to general assent. However, as Baker pointed out: “We are seeing our customers buying their own printers so if suppliers start actively targeting those as new sales channels that will have an impact.”

This Round Table was sponsored by HP which suggests the following websites may be of interest to you: http://h10088.www1.hp.com/cda/gap/display/main/index.jsp?zn=g ap&cp=20000-13698-16020_4041_100__ uses tabs corresponding to ‘printers’, ‘solutions’ and ‘supplies’. So, for instance, you can select a printer, such as XL1500, and you will find ‘media list’, ink details, potential upgrades and their benefits. There are ‘white papers’, technology backgrounders, stories from other users etc. http://www.hp.com/hpinfo/globalcitizenship/environment/product data/lfmsdsuseng.html is also a useful link with all MSDS. Image Reports will be conducting a number of Round Tables during 2010. If there are specific issues you would like to see discussed please contact the editor Lesley Simpson. Email Lesley.Simpson@imagereportsmag.co.uk

{jathumbnail off}