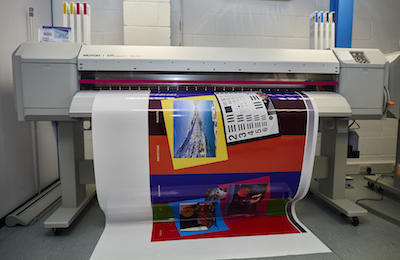

Nessan Cleary conducts a test to check whether this printer lives up to its promise to deliver good quality results at a relatively low cost.

The Japanese manufacturer Mutoh has been around since 1953, having started off making drafting machines before moving into wide-format inkjet printers. The mainstay of the Mutoh printer range currently is its solvent series, including the ValueJet 1638X that was launched earlier this year and the focus of this test.

This printer takes media up to 1625mm and prints up to 1615mm in width. It uses two Epson DX7 printheads, each of which has 180 nozzles per channel, with eight channels. This has allowed Mutoh to set the printer up with two sets of CMYK, and to stagger the heads so that they cover a 2in print swathe. These are greyscale heads, producing drop sizes from 3.5 to 35 picolitres.

However, it’s also worth noting that there’s no head guard to protect the printheads, so you’ll have to be careful as head crashes are the main cause of failure with any inkjet printer. Jeff Biggs, managing director of Mutoh’s UK distributor, Colourgen, explains that this is mainly because the Epson heads cover quite a large area, making them difficult to protect effectively. But he also points out that Mutoh has been able to get the heads closer to the media surface, which should make the drop placement at higher speeds more accurate.

The printer uses Mutoh’s intelligent interweaving system, which is designed to reduce the effects of banding at higher print speeds. Normally a large-format image is laid down in lines as the heads pass back and forth over the media. But this system lays the ink down in a wavy pattern rather than a straight line.

The printer uses Mutoh’s intelligent interweaving system, which is designed to reduce the effects of banding at higher print speeds. Normally a large-format image is laid down in lines as the heads pass back and forth over the media. But this system lays the ink down in a wavy pattern rather than a straight line.

For its dual head printers, Mutoh has also developed DropMaster, which can make minute adjustments to the way it fires the ink based on the thickness of the media, since the surface of thicker media is effectively closer to the print nozzles than with thinner materials. This printer can handle media from 0.3mm to 2.8mm in thickness, which is enough of a difference to affect the accuracy of the drop placements, which in turn can lead to fuzzy images, particularly at higher speeds. Thus DropMaster works by using the media profile to tell the Rip how thick that media is, which then automatically sets the height of the printheads and adjusts the way the ink is fired.

As with most solvent printers, the VJ1638X has three separate heaters – pre-heating to open the pores in the media, the platen itself to start the drying and fix the ink drops, and a large post-heater to dry the prints. However, most of the solvent printers we’ve looked at have also had a set of fans behind the print carriage to blow the heated air across the surface of the print and help to dry the print, without any danger of overheating the media.

The VJ1638X lacks these fans, which in our experience means that the profile has to be exactly right for the media in use. If there’s not enough ink, the image will be washed out, but if there’s too much ink then it won’t dry quickly enough before the print reaches the take-up roll. However, get the profile right and the printer is capable of very pleasing images.

The VJ1638X lacks these fans, which in our experience means that the profile has to be exactly right for the media in use. If there’s not enough ink, the image will be washed out, but if there’s too much ink then it won’t dry quickly enough before the print reaches the take-up roll. However, get the profile right and the printer is capable of very pleasing images.

The heaters turn off automatically when one job finishes to save power, which means that you then have to wait two to three minutes for them to warm up again before the next print, so that it pays to queue jobs up to keep the printer running continuously.

There’s also a choice of inks, between the Eco Ultra and the slightly more aggressive UMS, which have good resistance to abrasion and a wider colour gamut. Biggs says that just about everybody goes for the UMS inks.

Maintenance is fairly simple, with a capping station on the left hand side and a manual cleaning area on the right side. The capping station includes a scraper blade and a pump that pulls a small amount of ink onto the heads to help dislodge any dried ink that might have formed.

It’s possible to run a nozzle check from the Rip, but all the maintenance has to be done from the front panel. It’s relatively easy to navigate through the sub menus on the control panel, and there are short cuts to the more obvious features such as cleaning and cutting.

It’s possible to run a nozzle check from the Rip, but all the maintenance has to be done from the front panel. It’s relatively easy to navigate through the sub menus on the control panel, and there are short cuts to the more obvious features such as cleaning and cutting.

You can also use the front panel to set up to 30 different media types complete with names so you know which is which. The media types also set the feed tension as some materials can stretch more than others.

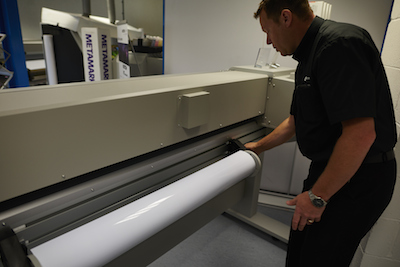

The printer will take media rolls up to 30kg in weight, though there’s no shelf to rest the media on, or any kind of assistance so that some people might find it a bit of a struggle to load the media on their own. That said, it is quite easy to line the media up from the back of the printer, where there’s a lever to clamp the media in place. There are optional take up systems capable of taking 80kg and 100kg rolls.

Costs

The Mutoh VJ1638X is distributed in the UK by Colourgen, based in Maidenhead, which has put together a sensible bundle for £20,995.

This includes the printer complete with a take-up system capable of handling 30kg. Colourgen has also added two bulk ink systems with eight 1000 ml ink bottles, which is by far the most economical way of running this printer. This deal also includes a Rip, with a choice between SAi and Onyx.

The 1000ml UMS ink bottles cost £89.95, while the standard 440ml cartridges cost £59.95, which is considerably cheaper than the Eco Ultra ink, at £95.95 for a 440ml cartridge.

ON TEST

For our tests we use two charts - one with mostly photographs and one with mostly solid Pantones. Both are A0-sized and we print each chart at both a high quality setting to assess print quality and at a typical production speed to assess productivity.

This printer is capable of 1080 x 1440dpi resolution, with 12 passes at 10m2/hr, but for our quality test we used 720 x 1080dpi with six passes, which should run at 20m2/hr, since this was the best profile available for the Metamark MD5 media that we printed to. For the faster prints we used 720 x 720dpi with four passes, which should produce between 29 to 36m2/hr. But Mutoh also claims that the printer will run at 94m2/hr at 360dpi with banner materials.

The actual print times varied a fair bit depending on the amount of coverage - from 4.04m for the photograph chart to 7.30m for the solid Pantones using the four pass 720 x 720dpi mode.

The times were more uniform in the six pass 720 x 1080dpi mode - 11.55m for the photographs and 12.34m for the Pantones. The photographs chart used less ink - 8.21ml in four pass and 7.19ml in six pass mode - versus the solid Pantones where we used 14.03ml in four pass and 15.15ml in six pass.

The chart with the photographs in four pass mode showed distinct banding patterns on solids. This has shown up in the reflex blue gradient panel, but also in the background on one of the photos and you would have to view the prints from several feet away before this became acceptable. There is still banding on the six pass print but this is very fine and disappears when viewed from a couple of feet away.

The Pantone chart four pass has shown very slight banding in the solids, barely noticeable close up and certainly nothing to worry about. The colour rendition is very good and the resolution is excellent with the text easily legible at three point, and just about legible in four point in white on black.

Conclusion

It has to be said that despite the intelligent interweaving system, this printer’s output showed the worst case of banding that we have seen yet in these tests. But despite this it is possible to get very good results from this printer in the higher quality modes and the banding isn’t noticeable at normal viewing distances.

The colours are reasonably vibrant, with good deep blacks and it has accurately reproduced text and fine lines. The results are definitely better in the slower, higher resolution modes but against this both the printer and its inks are quite reasonably priced.

{jathumbnail off}