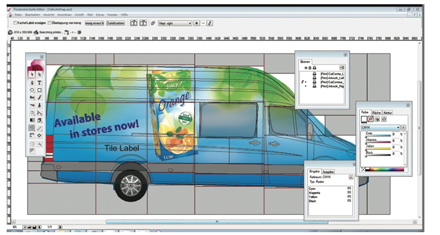

The Chinese brand Longier is offering a reasonably priced flatbed printer, but how well does it perform in practice? Nessan Cleary asks user Paul Serellis of Eazy Print in Eastleigh.

From time to time you come across a new player in the wide-format inkjet printer market, such as Longier. Its range is built in China but now available in the UK and Europe courtesy of Gary Hall of Hallmark Equipment Services. The first of these was installed over the Christmas period at Eazy Print, based in Eastleigh in Hampshire.