Nessan Cleary investigates this high-speed textile printer aimed at the soft signage market.

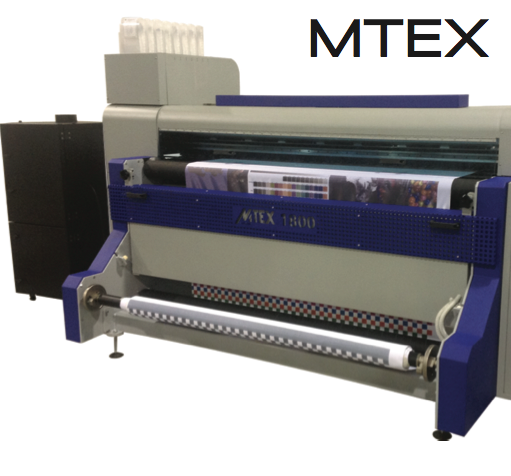

Earlier this year the Portuguese company POD added a new textile printer, the Mtex 1800, to its line-up of fabric printers which are all distributed in the UK by the Derby-based company Digital Print Innovations, or DPI.

This is a 1.9m wide printer with built in fixation, aimed at the soft signage rather than garment market. The model will effectively replace the older Mtex 1600. It’s built around the chassis of a Mimaki TS34, POD being only one of three companies officially licensed by Mimaki to adapt its machines. Using an existing chassis saves a lot of cost and development, though there’s far more to this than a simple OEM arrangement as POD has added a number of additional features so that you would be hard pressed to recognise the Mimaki DNA on the finished printer.

Stewart Bell, managing director of DPI, says that it’s a completely different machine, noting: “All the control systems are different. It runs a lot faster than the Mimaki - up to 65m2/hr.”

The main addition is an inline infrared fixation unit, which can operate at the same speed as the printing unit. Bell explains: “So you are printing direct to textile and this then passes through the infrared unit. There is an extraction fan that takes away the steam so you don’t need a separate calendar. It’s an all in one complete solution.”

The Mtex 1800 uses tension rollers to move the material through the printer. By their nature textiles have a certain amount of give but to counter this the printer makes automatic adjustments to the various systems, based on profiles supplied with the media by DPI. All the components within the printer communicate electronically so that the media transport, the amount of ink laid down and the degree of fixing can all be adjusted to suit the material in use, all based on information in the ICC profiles, which DPI has put together. It does require the operator to keep an eye on the printing but Bell says that most users pick it up fairly quickly and that the profiles have taken most of the mystery out of the process.

It has a four-colour inkset, using magenta, yellow and black, but with blue replacing cyan for a more ‘punchy’ blue. The inks are supplied by POD and come in two litre bulk packs, which are said to be easy to load.

The printing engine uses two Epson DX6 printheads arranged in a staggered configuration, which give it a wide printing swathe, helping to keep the speed up. Resolution is 1400dpi, with three variable droplet sizes. As such, it’s capable of 65m2/hr in its high-speed mode, but there’s also a production mode of 35m2/hr for higher quality.

The printer uses water-based disperse inks which are standard for dye sublimation and will print to polyester, providing there is 70% polyester in the media.

The Mtex 1800 is designed to cater for the soft signage and interior decoration markets. It prints to a range of media including display, backlit, beach flag, silk, backlit and canvas. It will also print to self-adhesive wall coverings, which is a growing market. It’s possible to use just the front heaters to avoid activating the glue in self-adhesive substrates. Bell says that the soft signage market is forecast to grow considerably over the next few years, pointing out that textiles are relatively cheap as substrates go and easy to work with.

POD has quite a line-up of textile printers now, including the Mtex 500, which is a high production machine capable of producing up to 100m2/hr, and the Mtex 3200, which is a 3.2m wide printer for banner production so this new Mtex 1800 fits nicely as a general purpose printer. It costs £59,950 but this includes the Rip and the installation, though it doesn’t cover the cost of a forklift. Installation takes about a week, but most of this is training the operators to work with textiles.