You know what technical advances you need to see if you’re to continue running a competitive large-format print business. So, are your suppliers delivering?

In ye olden times - like 2020 - we’d have been running print trade show previews in this February/March issue, highlighting new solutions in response to what the manufacturers understood to be the large-format market’s clarion calls. With 2021 events cancelled/postponed, we instead asked a broad swath of the sector’s hardware and software manufacturers what technical demands they were receiving from PSPs - and what they were doing in response.

There was collective recognition of key issues such as the need for solutions that provide greater flexibility, versatility, help shorten turnaround times and reduce printed product unit costs - for those that enable PSPs to differentiate their offering, maximise new markets like personalisation and online ordering, that help meet customer demand for project traceability and instant updates, and that improve the ability to work remotely, do more than just make a nod to sustainability, and that are part of a secure ongoing supply chain. Reducing ink consumption, improving Rip times, better colour control, more systems integration, automation, remote servicing, greening-up the kit manufacturing process - all of these things, and more, are being addressed. So what can you expect from which manufacturers? Here’s what the individual companies had to say…

Agfa

Agfa’s Bobby Grauf: We have exciting plans to expand our software suite in 2021.

“Efficiency gains and cost control will remain prevalent demands,” says Bobby Grauf at Agfa. “So, we have exciting plans to expand our software suite in 2021, which we strongly believe will be another milestone in the company’s history of integrated workflow solutions.

“Also, we are continuously researching different ways to reduce ink consumption without loss of quality, whilst aiming to expand the media scope without the need of additional chemicals. We are very excited that our new ink development came to the UK in January 2021 as part of our global field test programme.

“On the system side, we grew our product families in 2020 and introduced new peripherals, such as the semi-automatic board feeder and integrated roll-to-roll options for the Jeti Tauro H3300 LED series. 2021 will see a continuation of our strategy to address all wide-format market segments.”

Canon

“The increase in online shopping has meant PSPs are competing for the fastest delivery times and looking to eke out any possible timesaving,” stresses Derek Joys, product marketing manager for large-format graphics, production printing products, Canon UK and Ireland. “More than 60% of LFG print jobs need to be turned around within 24-hours, so technologies that accelerate efficiency and productivity will be in demand. One example of this is Web-to-print, which taps into new e-commerce opportunities. Time savings are now essential in this highly competitive market. Innovations such as automated workflows and increased robotisation are helping companies to meet ever-increasing time demands, with the additional benefit of driving down costs.

Joys adds: “Sustainability has also become a business imperative for all companies and PSPs are looking to ensure that it is woven into every aspect of the printing production process - including the inks and materials used, emissions released during the printing process, as well as the energy consumed by the device. Manufacturers are also looking for ways to maximise their continuous use of resources by implementing remanufacturing processes.”

Color-Logic

“Large-format PSPs are seeing the need to help clients differentiate themselves from their competition. Many printer manufacturers have introduced white ink, and now many are adding extended colour gamut (ECG) inks to help with this differentiation,” says Mark Geeves, director of sales and marketing.

“Touch7 Photo ECG by Color-Logic is a Photoshop Plug-in that enables the same inks to be added into images with just one mouse click. Color-Logic and Touch7 continues to develop design software enabling creatives and prepress personal to utilise the new inks being developed by the printer manufacturers.

Durst

According to Peter Bray, MD of Durst UK and Ireland, the company has noted three key areas of interest - versatility, sustainability and functionality.

“Some of the demands and challenges we are seeing from the large-format print sector cover JIT orders and deliveries, short-run orders, 24x7 service and the ability to work from everywhere. Customers also want to know what the final product looks like (WYSIWYG), plus expect traceability and instant update capabilities,” he says.

Bray points out “customers are increasingly looking to invest in a hybrid solutions.” In response Durst developed its P5 technology platform, “which we believe is the Swiss army knife of printing because it has so many uses. The introduction of the new Durst P5 350 High Speed version in the first quarter of 2021 will become a key pillar in our ‘Pixel to Output’ strategy. It comes with Automat, a new automatic system, enhanced Durst software and a full LED ink portfolio. We provide Durst Smart Shop, workflow and analytics software, the latter being the basis for future sales and profitably.

“In our mission to become a complete solutions provider, we have also worked extensively on the Smart Factory. We are convinced it should be a 360-degree business solution covering customer experience, process automation and production line automation.”

Durst’s new P5 350 high-speed version builds on its ‘Pixel to Output’ strategy.

Epson

“I would say that the requirements from PSPs on signage during the last year haven’t really changed that much, but with textile and promotional goods the trend towards personalisation has accelerated, says Phil McMullin, sales manager, prographics, Epson (UK), suggesting that in 2021 that’s where its focus will be.

He adds that, “sustainability is still a big topic. Signmakers want to print onto non-PVC media so this means more environmentally friendly products. Our new resin ink printer has water-based ink and low temperature curing. Likewise the fashion industry is also focusing on sustainability. Our dye-sub and DTF inks enable consistent, vibrant prints on many of the new man made textiles that copy nature products.”

Esko

“Today’s large-format PSPs operate in a highly competitive market, with an ever-growing demand for increased accuracy, consistency and efficiency as a direct consequence. Without a doubt, the innovation delivering the clearest tangible benefit to businesses in meeting this challenge lies in the integration of hardware and software and automating workflows, systems and processes,” stresses Russell Weller, product manager, digital finishing.

“Acceleration in digital transformation means automation, for example, will go far beyond individual machine or process step automation, but will necessarily have to be considered at site, business and multi-geography level.

“Doing more with less is a key value proposition of Esko solutions, and the Esko Digital Maturity Model provides inspiration and vision, and most importantly, a strategy for businesses to solve some of the issues highlighted by the Covid-19 crisis. For example, Kongsberg finishing equipment integrates with Esko workflow automation software to enable maximum productivity and efficiency, even in the face of a reduced workforce.”

Esko’s Digital Maturity Model

Fujifilm

“Looking at future demands or needs, we need to distinguish between high-volume PSPs and small-mid size PSPs, says Nils Gottfried, product marketing manager EMEA WFIJ and packaging at Fujifilm Europe.

“The high-volume PSP will continue to focus on automation, faster job turnarounds and economic production at the highest quality. Smaller and mid-size PSP without in-house sales staff and strong networks to agency and brands are going to focus very strongly on the lowest cost of production, without loss in speed and quality. Automation is not a very strong focus for these companies due to the higher investment cost and lower print volumes. For both customer groups, Fujifilm can provide print solutions that serve the need to be competitive both now and in the future.”

Global Graphics

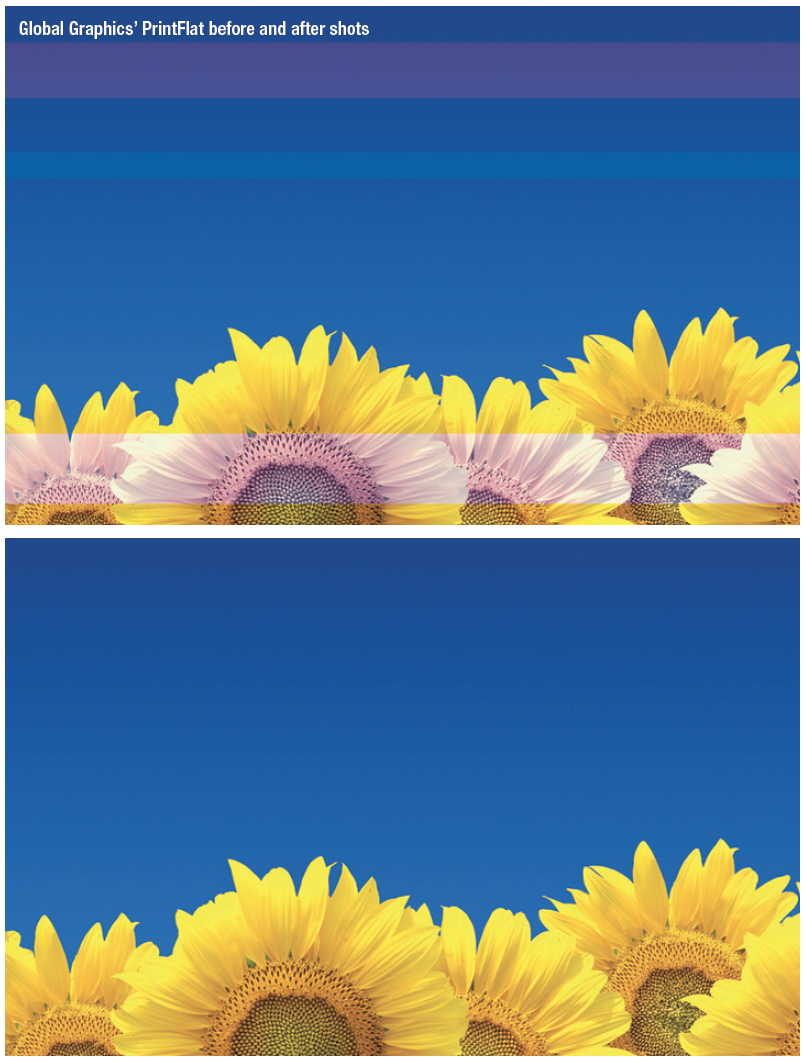

According to Justin Bailey, “a major technical demand is for improved inkjet output quality,” and he points out that “banding due to non-uniformity is a key factor in why some jobs are unable to be printed digitally.” He adds: “The solution is PrintFlat which can be used in any workflow with any existing software solution - with it a PSP can achieve higher quality in faster print modes.”

Bailey reminds us that in 2020 Mutoh and Mimaki adopted the company’s Harlequin Rip - already used by Roland to drive its wide-format devices. “OEMs tell us that it is important their customers see shorter Rip processing times for PDFs and improvements in PDF processing quality. They also want their customers to be ready to receive PDF 2.0 files so that there is no disruption to their workflow.”

GMG

GMG’s Paul Williams: Two key trends are driving R&D in colour control.

At GMG, sales manager Paul Williams says that when it comes to colour control there are two main trends driving technical developments and thus impacting its R&D. “Firstly, it’s becoming more common for brand customers to supply LFP printers with colour references to match, such as CxF data or L*a*b* references. And secondly, brands are increasingly asking PSPs to produce to particular standards - mainly Fogra 39L in the LFP area, as well as Fogra 51 and 52.

“Where brands are giving work to several different companies, they’re expecting the same results from each. We have clients using certified GMG contract proofs in conjunction with GMG ProofControl. A Fogra media wedge is included within the print run, read using GMG ProofControl and compared to the required standards, i.e. Fogra, GRACoL, or a brand’s own bespoke colour standard.

InkTec

For InkTec’ Europe’s Peter Davidson, head of IP consumable sales, reduced staffing levels due to Covid-19 and a subsequent loss of technical skill is something the company is focussing on.

“Sadly we have seen a number of people disappearing from the sector as companies consolidate their workforce. As a result, we have seen an increase in enquiries asking for InkTec to fill a void with technical support.”

He adds: “The loss of technical knowledge will become a much bigger challenge for many companies. To address this, InkTec Europe are already considering how to make this type of information more accessible and user friendly.”

Kornit

Kornit’s Phil Oakley: DTG printing workflow developments are key.

According to Phil Oakley, UK&I country manager, the desire by large-format PSPs to build upon opportunities within the direct-to-garment market means it’s seeing a number of technical demands, particularly in terms of workflow management.

“How can PSPs enter the market in an efficient manner to make order taking, entry, production, and pack-and-ship as automated as possible? A PSP’s ability to understand the printing technology and managing Rips, colour management, and operating the equipment is actually the easy part. How to acquire and manage workload in the most efficient and fastest manner is the speciality they will need to succeed.

“DTG is a very fast-moving market where the management of orders through to fulfilment is dynamic and often chaotic. Combining technology to load balance jobs across platforms and then automate the production and fulfilment is where they should be looking to invest to tame the workflow and make it efficient.”

Oakley says Kornit is looking into new capabilities that will enable PSPs to increase their workloads, streamline the end-to-end production workflow, adapt to evolving and sudden changes in consumer demand, increase production efficiency and sustainability, deliver new applications in both popular and niche fabrics, establish more beneficial business models, and ensure long-term profitability while producing only what is sold.

Mimaki

“Companies are asking for solutions that enable them to diversify and turn work around quickly,” reiterates Brett Newman, MD of Mimaki’s exclusive UK/Ireland distributor Hybrid, pointing to the resultant introduction of the UJV100-160 early this year.

“This is a much requested iteration of Mimaki’s LED UV technology. Since the launch of the UCJV300 Series LED UV printer/cutter in 2017, we have sensed the opportunity that a print only version could offer, and the UJV100-160, with its choice of higher capacity 4-colour output or quick process-plus-white configuration has whetted a lot of appetites. The beauty of the new UV printer is its combination of price, performance, creative potential and ease of use in response to demand for an entry-level solution with all the breadth of application of pricier machines.”

Onyx

Onyx’s Jonathan Rogers: PSPs want tools that provide integrated solutions.

“PSPs are asking for tools that provide integrated solutions aimed at reducing manual error and increasing automation from design file to printed product,” says Jonathan Rogers, international marketing manager at Onyx.

“From a technology standpoint, software providers have responded by offering end-to-end solutions with increased speed and performance, such as utilising multithreading to send more data to printers faster; improved core Rip technology that instantly recognises design file settings; digital cutting automation for print-and-cut workflows; data management tools to help reduce waste and manage print production costs; and easy-to-use automation controls that can be applied from pre-press through to finished prints.

“What 2020 has taught us is that digital PSPs can adapt, seeking out new opportunities. Software vendors have responded with technology to support them, something we expect to continue as we look into 2021 and beyond.

Roland DG

Rob Goleniowski, head of sales UK and Ireland, points out that it has become vital for PSPs to strengthen their online presence to capture the increasing online market and that in response Roland DG launched PersBiz, a digital webshop that enables companies to start selling online and provide personalisation options. “But the work shouldn’t just stop once an online presence is established. PSPs need to stay on top of important algorithm updates in an ever changing wide-format sector,” he stresses.

SAi

At SAi the focus in on two things - flexibility and integration. On the first point SAi says the uncertainty that Covid-19 has had on trade is prompting more PSPs to consider the software on subscription model. On the other point, the company points out that it is integrating across its Flexi signmaking and EnRoute CNC CAD/CAM software to help streamline processes.

Summa

“Modularity is now more important than ever, allowing PSPs to expand their applications range without high risk to the health of their business,” says Daphne Mertens, marketing and communications. “The digitisation in the textile industry pushes for shorter runs, more personalised products, faster delivery times and zero finished product stock. Summa professional laser cutters such as the L1810 and L3214 allow PSP’s to follow demand while the market is in full ramp-up.”

She adds: “The uniformity of the Summa cutting workflows is also a great perk - and the intuitive software includes automated presets, allowing less skilled operators to use quite complex large-format cutting machines.

swissQprint

“The pandemic has created a dynamic trading environment. A versatile printer, as well as application and technical know-how, is needed to capitalise on a new opportunity,” sums up swissQprint, pointing out that in terms of technical demand and development, versatility, reliability and performance continue to be ubiquitous in large-format in the UK at this time.