Increasingly, inkjet printer manufactures are extending their reach by adding industrial printers to their offering? But, what do they mean by ‘industrial’, and do machines matching that definition have any place within graphics sector PSPs?

What makes an industrial printer just that? Is it a question of productivity and volumes, of application type and capability, of where it fits into a manufacturing process, a mixture of all the aforementioned? Does it even matter if they’re not aimed at your type of business? Or are they? As manufacturers extend their product portfolios we asked a selection of them to define ‘industrial’ printer and market positioning to try and clarify just how relevant they are to the wide-format graphics sector.

Let’s start at the alphabetical beginning, with Agfa. Bobby Grauf, sales manager UK and Ireland, says: “Industrial is a core ingredient in all our solutions - whether it’s a lower investment point with Anapurna or a higher one with Jeti. In our eyes, printing begins with fast, error-free delivery of print files to the pressroom. The ability to process jobs ensures the printers are fed with the right data at the right time. Every PSP can benefit from this approach, which is the first step to industrial printing.

“Next, one can look at loading and unloading times, and how those can be optimised with automation.

“Then there is another element in regards to industrial print, which is the integration of our products in adjacent industries. A good example is our flooring solution InterioJet, which uses a large part of the Jeti Tauro Series as its base but is modified to run special flooring papers with Agfa-made water-based inks. Another one is leather printing with the Agfa Alussa. Again, we start with a Jeti Tauro, but here we have adjusted transport mechanisms to hold the leather on the belt, print with specific, ultra-flexible UV LED inks, and finish off with bespoke coating to protect the finished product from scuffing and scratching. These two solutions, as well as dedicated inks for other industrial sectors, form our Industrial Inkjet segment.”

At Canon, Derek Joys, product marketing manager, production printing products, says: “When we refer to industrial printers, we are usually referencing applications that are outside of the graphics and signage markets. More specifically, this may refer to when the printing of a substrate forms only one part of the application manufacture. An example of this is membrane switch printing, where printing is just one component of the control panel of the machine.

“All of Canon’s large-format printers, whether flatbed or roll to roll, are built to an industrial standard, and are designed to suit many markets.”

“What I refer to as ‘industrial’ production is 24x7 operations and where the key focus is on reliability with minimal downtime,” explains Peter Bray, managing director, Durst UK and Ireland. “Ceramic, textile and corrugated markets spring to mind as good examples of continuous production.

“More recently, we have introduced Durst software and analytics that are enabling customers to better understand productivity and how to make the best use of their technology.

“As to the question of who the ‘industrial’ machines are aimed at, it depends on the individual circumstances and set-up. If you are talking about large PSPs, these days, many would be expecting to run 24x7 operations and would be talking about industrial-scale production. On the other hand, a small graphics house or sign maker might need a machine that produces only two-three hours of work per day. The tipping point for the ROI is always going to be somewhat difficult to nail down in general terms. For me, the answer would depend on a number of factors, which will include the type of applications being produced and at what price being sold.”

Phil McMullin, head of sales commercial and industrial printing, Epson (UK), points out that the company addresses the industrial sector with two distinct strategies.

“Firstly, Epson sells its Piezo inkjet printheads to other manufacturers for integration into industrial printers. In addition, we have two printer ranges that specifically address the industrial print space - the SurePress family of label presses and Monna Lisa range of textile printers. The SurePress machines were developed for label converters. However, they are also proving popular for high-volume sticker production, particularly in Europe and the US.

“For the direct-to-fabric sector, the Monna Lisa Evo Tre is the well-established industrial digital textile range based on total solution - a fully integrated system where all components belong to the same process to guarantee the best printing results. This is the result of the synergy of Epson inkjet printing technology with engineering by Robustelli and pre/post-treatment and inks by For.Tex [both now part of Epson]. The Evo Tre range has recently been complemented by the introduction of the entry-level ML8000 printer.”

For Jane Rixon, business development manager for signage and decoration, HP UK and Ireland, “there is something of a conflict between perception and reality when we consider the term industrial print, and/or what might qualify as an industrial printer.”

She explains: “The perception is that ‘industrial print’ can be defined by the purchase cost or performance level of the printer - if the printer costs over £25,000 or the production performance levels cross a certain volume threshold, then many might consider that printer as being ‘industrial’.

“The reality - and certainly from the point of view of most manufacturers - is that true industrial print is more likely to be defined as print applied as part of a more elaborate and far-reaching manufacturing process, one where the print itself is not the final product, but rather the items printed - for a decorative or functional purpose - are simply a component of the end product.

“Decor applications, for example, could be considered to be industrial, but only when on a large scale. One printed piece of wall art wouldn’t be considered industrial, but rolls of wallpaper produced in volume as part of a larger industrial manufacturing process could be.

Equally, you wouldn’t describe print as being ‘industrial’ when you’ve printed a single door on a flatbed printer - it’s not manufacturing, and it’s certainly not industrial in scale. But inkjet printing integrated into a laminate flooring production line, used to apply a decorative grain effect, is most certainly an industrial print process.

“There are relatively few graphics PSPs that currently have a full-scale industrial print set-up as part of their offering - not least because the demands from their sales channels differ so vastly. The technical and production support requirements for an industrial business are also very diverse.

Ben Woodruff at Jetrix classifies an ‘industrial user’ “as a company that is printing for its own use. For example, we have a customer that uses its Jetrix LXi8 to print 6,000 vehicle number plates every day. We have another that prints the glass fronts for gaming machines. Another uses a Jetrix LXi8 to print office dividers and glass partitions. A funeral director uses one to print coffin lids. In fact, I would say that between 20-30% of our Jetrix user base in the UK could be classed as industrial now.”

He adds: “The leading UV flatbed printers are well-built, making them equally suitable for the graphics market and the industrial sector. Entry-level machines start around £65,000 which when financed over 5 years is not much different to leasing a car.”

Duncan Jefferies, head of marketing and business development at Mimaki’s distributor for the UK and Ireland, Hybrid Services, says: “In our experience, the term ‘industrial printing’ can be defined by a number of factors. At its simplest, it’s assessing at what volume print becomes ‘industrial’, and a lot of the time that will be down to the print provider themselves to define. We have many Mimaki installations where companies are running an industrial printing operation, producing high volumes of print as part of a manufacturing process (a good example being sportswear, fashion and homeware production companies), however their hardware may be the same as a smaller textile design company - it’s just that they have more of it.

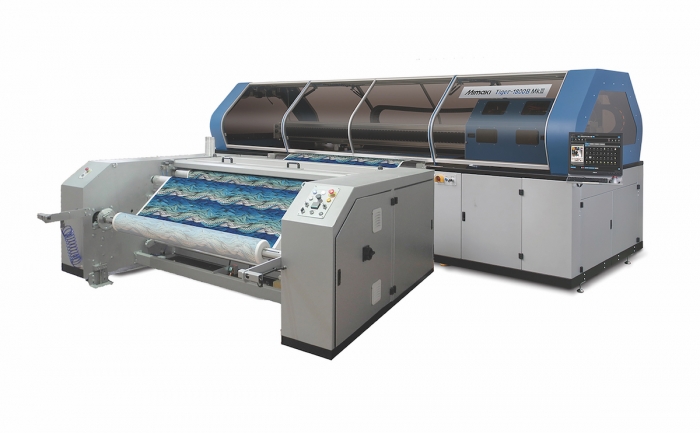

The Mimaki Tiger-1800B, one of a number of ‘industrial’ large-format printers on the market today

“Equally, Mimaki offers multiple industrial hardware solutions including the Tiger 1800, a textile system capable of outputting almost 400m2/hr. Its size and productivity make it every inch an industrial solution.

“In many cases, companies benefit from the flexibility they get from running a bank of machines and equally, the built-in redundancy of having the reserve of one or more machines in the unlikely event of a technical issue. But, of course, opting for a ‘typical’ industrial machine has some definite advantages too. Consumables costs are generally going to be lower because of the volumes involved and there may be reduced staffing costs as well.

“However, Mimaki’s latest tranche of products sport many of the labour saving core technologies that have cascaded down from its industrial solutions. So the products most commonly invested in by PSPs can be utilised as a multiple installation for industrial volumes of output.”

The final word comes from swissQprint, which puts it rather succinctly: “A large-format industrial inkjet printer is designed to support a 24/7 manufacturing operations that need to minimise defects and ensure high equipment availability or uptime, while printing at the highest possible performance.

“There is certainly a place for industrial printers in the graphics sector PSP - one of the reasons the swissQprint Nyala has been the best-selling UV printer in Europe for the past six years.“