In theory GMG ProductionSuite separates the prepress from the ripping for greater production efficiency, so what’s it like in practice? Nessan Cleary asked users.

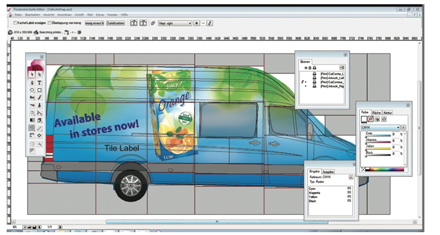

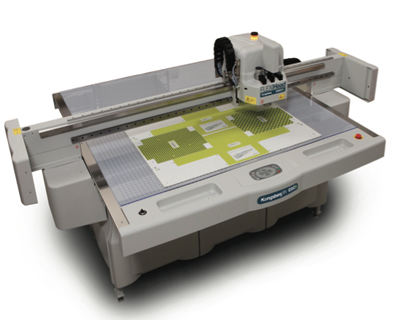

We've long been advocates of using workflow programs to organise production departments more efficiently, so it seemed like a good idea to look at one such system – GMG's ProductionSuite – in more detail. This should separate prepress functions from the output in order to squeeze the maximum efficiency from both halves of a job. It can oversee multiple printers so that jobs can be routed to the most appropriate device, even late in the production process. It can take care of difficult issues such as colour management and finishing marks and offer centralised management of every job in production.