New automation has been added to Fujifilm/Inca Digital’s Onset X HS large-format series printers to improve productivity.

There are now four automation options for the Onset X HS range - a three-quarter semi-automatic system, a fully automatic material loading system, a fully automatic handling system for unconditioned corrugated board, and a fully automatic handling system with integrated flexible loading.

The three-quarter automation system allows for single sheet, multiple sheets or double-sided print in registration. The operator loads sheets onto a preload table and the system takes over the rest, stacking it on a pallet for removal of the printed media. The system allows the operator direct access to the bed and registration points for quick switch between manual and semi-automatic work.

The fully automatic material loading system is designed to handle conditioned and dimensionally stable sheets and works in conjunction with the three-quarter handling unit to provide full automation. The loader can be moved away from the machine to allow access to the print bed.

The corrugated board solution incorporates a fully automatic handling system, designed to handle difficult materials. There is vacuum-to-vacuum transfer from the robotic arm pickup to placement on the print bed and stacking of the printed board.

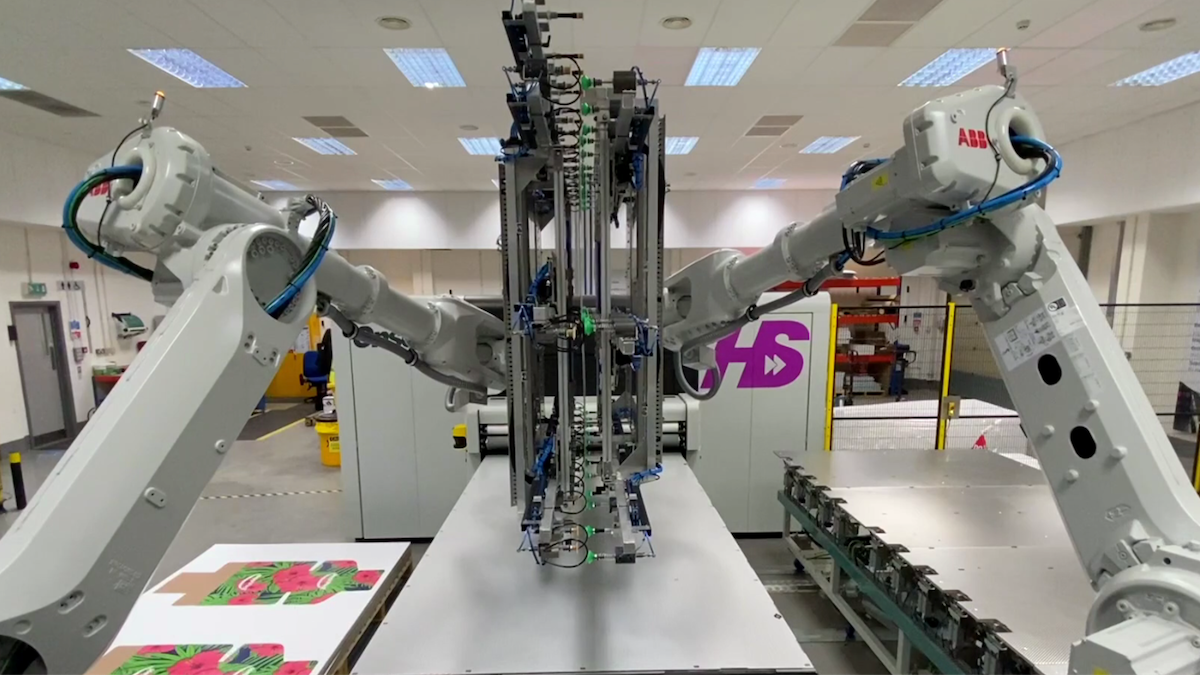

Dual Flex is the fully automatic solution with integrated flexible loading that enables printers to transition seamlessly between lay table loading and dual robot automation. This solution provides full capability to load and unload flexible, semi-rigid and rigid sheets with a seamless switch from one operation to the other. In full automation mode, the dual robots also offer an optional ‘flip to print’ mode - ‘High Five’ robotics - for front to back, double sided print requirements without manual intervention.

“The new automation options available with the Onset X HS range are the result of close collaboration with our current Onset X customers,” said Matt Brooks, head of products and solutions at Inca Digital. “Longer run, full automation is becoming more and more common, and with the introduction of highly sophisticated robotic arms from ABB and Inca’s sheet pick-up technology, Onset X customers can now produce extremely high volume, high quality print work in even less time. The ultra-high productivity and rapid job changeovers optimise production levels like never before.”

Kevin Jenner, European marketing manager, Fujifilm wide-format inkjet systems, added: “Fujifilm has enjoyed a long and successful partnership with Inca Digital since the two companies together pioneered the world’s first wide-format UV inkjet printers in 1999. The Onset X range has been setting the standard for quality and productivity in the sector for some years now and we’re delighted to be able to offer our customers yet another step up in speed and efficiency.”