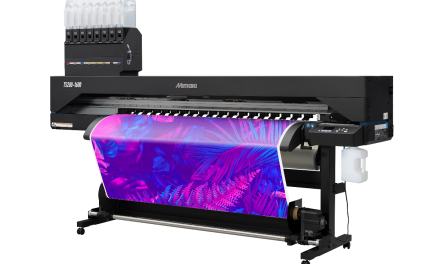

Roland’s TY-300 gets an upgrade

Printer manufacturer Roland DG has rolled out a series of updates to its TY-300 DTF printer.

The enhancements are engineering and performance-based, designed to support high-duty-cycle apparel production.

They allow the printer to increase ink system capacity, improve white-ink stability and workflow optimisations.

At the centre of the update is a doubling of the white-ink reservoir capacity, addressing one of the most demanding components of the DTF workflow.

The updated TY-300 maintains print speeds of 10.9m sq/hr in standard mode and 17.48m sq/hr in high-speed mode, delivering 50% higher productivity than comparable DTF units.

Reliability has also been strengthened through updates to the automatic maintenance system, including continuous ink circulation, scheduled head-refresh cycles and user-replaceable maintenance components engineered for minimal downtime.

Smart circulation stabilises white-ink flow during idle periods, reducing clogging and purging requirements whilst extending printhead life.

For production environments with multiple operators, these automated systems contribute to predictable performance and reduce manual intervention.

Ryugo Nimura, executive officer, global sales and marketing division at Roland DG, said: “DTF continues to evolve at a remarkable speed, and we know our customers rely on stable, high-performance systems that can sustain heavy production workloads.

“With the updated TY-300, we have enhanced core components that directly impact throughput, uptime and ink stability. These improvements ensure the TY-300 remains the benchmark for technical performance and production efficiency in the DTF category.”

The updated printer is available on global markets from today.