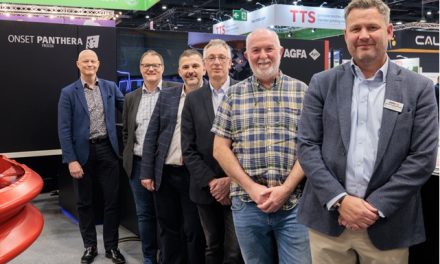

John is third from the left in the black t-shirt and grey beard

John Langfield, design process and digital manager for Muraspec Decorative Solutions, explains the impacts of the industry on the company and why the swissQprint Karibu is his favourite printer.

What is having the greatest impact on your business at the moment?

In a positive sense, there remains strong desire for inventive and bespoke wallcoverings from the design community across the world.

As a manufacturer and major exporter of goods, current political and commercial instability means distribution of product, and our supply chains, need to be under constant review. Legislation variances across regions are also becoming less harmonised.

Where do you see the greatest wide-format opportunities?

We specialise totally in wallcoverings so we typically look for market and design opportunities rather than any radical diversification into other wide format markets. Although we do have some things up our sleeve!

What would/is making your day-to-day operations easier?

My team are really skilled and conscientious, so they honestly make every day easier. The move to a staff-owned business this year also gives everyone involved a sense of ownership.

What is your favourite bit of kit?

Currently the swissQprint Karibu. In the distant past we had an old six-colour Halley Gravure press, with a 1960s Eltromat registration system, all dials, and seven-segment LCDs. Really hands on entry into the print world. Took hours to set up but there was nothing better than hearing the clattering of everything speeding up once the machine was in register.

What is the best business advice you have been given?

Don’t expect to get everything right, accepting this helps to grow as a person and business.

What is your proudest achievement?

I’ve been a key part in taking digital from start-up, with just myself using third party printers, to a recognised brand leader across the globe.

How long have you been in the industry? What attracted you to it?

I’m in my 32nd year at Muraspec. I actually delayed a university place after art college to take a year out and work. This was supposed to be temporary! I was asked to take on commissioning of a new gravure press shortly after starting then managed the introduction of CAD into our workflow soon after, having art and production experience. Adding in digital workflow and production soon followed. So I’m grateful I had opportunities to grow here.

What is the key to your business’ success?

Preparedness to adapt. When I started we had run lengths where 30,000 to 40,000 metre orders were not uncommon in the factory. We’re now much more nimble in being able to offer a wider and more exciting inventory, plus bespoke solutions with much shorter run lengths.

You have recently purchased your second roll-to-roll Karibu printer from swissQprint, after purchasing the UK’s first in late 2021. Why this machine and how has it helped your company?

I first tested swissQprint in 2012 and the print results were brilliant, but we really needed a dedicated roll-to-roll format which they didn’t have at the time. When the Karibu was introduced it was immediately high on my list. The fact it has a large platen for sampling is a huge benefit to us too as we make so many design samples without needing to load product rolls. Unattended overnight printing on large rolls is also a huge benefit to us too.

What are your impressions of the printer?

It really is of the highest quality. Well-engineered and easy to use. We’ve not had an unplanned service call in over three years.

Has your company lined up any future investments?

Yes… but that’s all I can say!