We’re seeing a high level of development and growth within the large-format inks space. So just what trends should you be watching out for? Richard Stuart-Turner investigates.

Technical

Eddie Williams, managing director, Agfa Graphics UK

Agfa is starting to sell it’s own branded large-format media in the UK, but what other strategic developments should we expect from the Belgian-based group?

Alexa, where’s my next print job?

Walter Hale considers the speed at which artificial intelligence is developing and at the argument for PSPs to get in on the act sooner rather than later.

Make it your own

Want to spend no more than £50 a month on a customised ecommerce website? Venture Banners may have the answer.

Race to the finish

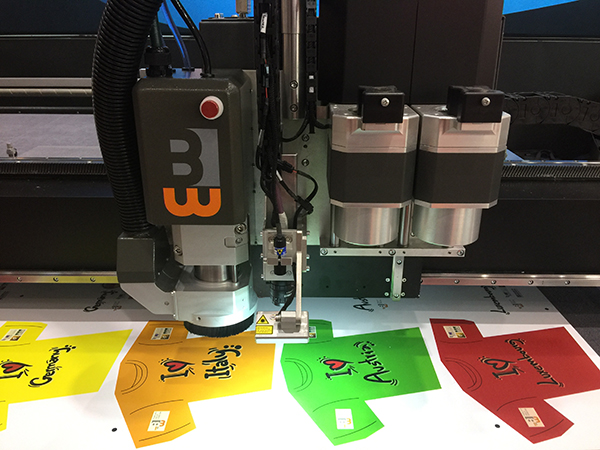

Automation is impacting finishing as it is the rest of the production process. But that’s not the only development focus when it comes to the end game as Richard Stuart-Turner explains.

The truth is out there

When mixed reality becomes, well, reality, how will you know what’s true and what isn’t? And how will that impact on visual experiences, including print? Walter Hale investigates.

Liquid assets

Walter Hale takes a look at Rapid Liquid Printing and its development potential.

Stuart Fox, director of digital finishing, Esko

The Kongsberg finishing table is the product everyone recognises from the Esko stable, but can you expect more than go-faster machines in a race to provide PSPs with better integrated workflow solutions?

Show me the way

What significant technical developments and trends were seen in large-format printers at Fespa and Sign and Digital UK? Richard Stuart-Turner reports.

Get ready for PDF 2.0

The first new version of the PDF specification since 2008 has just been published by the International Standards Organisation. So what will be the impact on print production of PDF 2.0 - the first post-Adobe standard? Martin Bailey, CTO of Global Graphics and the primary UK expert to the ISO committees working on PDF, PDF/X and PDF/VT provides pointers.

Quantum leap

Walter Hale looks at the developments in quantum computers and whether the technology could take business into another dimension.

Jeppe Frandsen, executive vice president industrial and production solutions, Canon Europe

In the last issue of Image Reports we reported on the launch of the first printer to use Canon’s much trumpeted UVgel technology. But how does the company’s R&D in this sector fit in with its own overall development strategy?

From design to delivery

What's new in the realm of design, workflow and W2P software, and how could these packages help your business? Richard Stuart-Turner finds out.

Ransom notes

Are you vulnerable to cyber attack? You may think not, but Walter Hale writes why you may need to change that thinking if you don’t want hackers holding you hostage.