Since YPS launched the Moditech Electronic Workstation (EWS) in the UK last year, it has been clear that this is a machine designed to make a huge and positive impact on the day-to-day operations of print providers and sign-makers. At Navigator Signing Solutions, the newly installed machine has already shown its value and is like having an extra team member.

Navigator Signs is a proper sign company. With offices in Newcastle-upon-Tyne and Glasgow, they have a long and respected track record in wayfinding and building navigation solutions. For many years they have been making signs of all shapes and sizes from all recognised materials, including aluminium, stainless steel, glass, bronze, brass, granite, acrylics and much more.

In more recent times, and to support the company’s success in winning contracts from university accommodation buildings, Navigator Signs has invested in more digital print and cut technology. Managing Director, Stewart Keepin, explains, “We are sign-makers with more than 80 years’ experience, but there are so many different elements to sign-making, it is very hard for a company of our size to deliver all solutions directly, and this means we sometimes need to outsource to other companies. However, as we are asked to do more work in certain areas, it makes better business sense to invest in the technology required to produce the work ourselves.”

Finding YPS

In 2022, Stewart was introduced to Newcastle based Your Print Specialists, a leading provider of a wide range of large format printing solutions. “We hit it off almost immediately. They understood our business, and we have been very happy with the products they have recommended and the service and support they have delivered,” says Stewart.

He continues, “We had a smaller printer and laminator, but having just won a large contract for a local University, we really needed something bigger and faster so that we could keep control of the job in-house and not have to outsource. We were having to cut vinyl by hand and put it through the laminator, which is a laborious and time-consuming process that we simply had to improve on.”

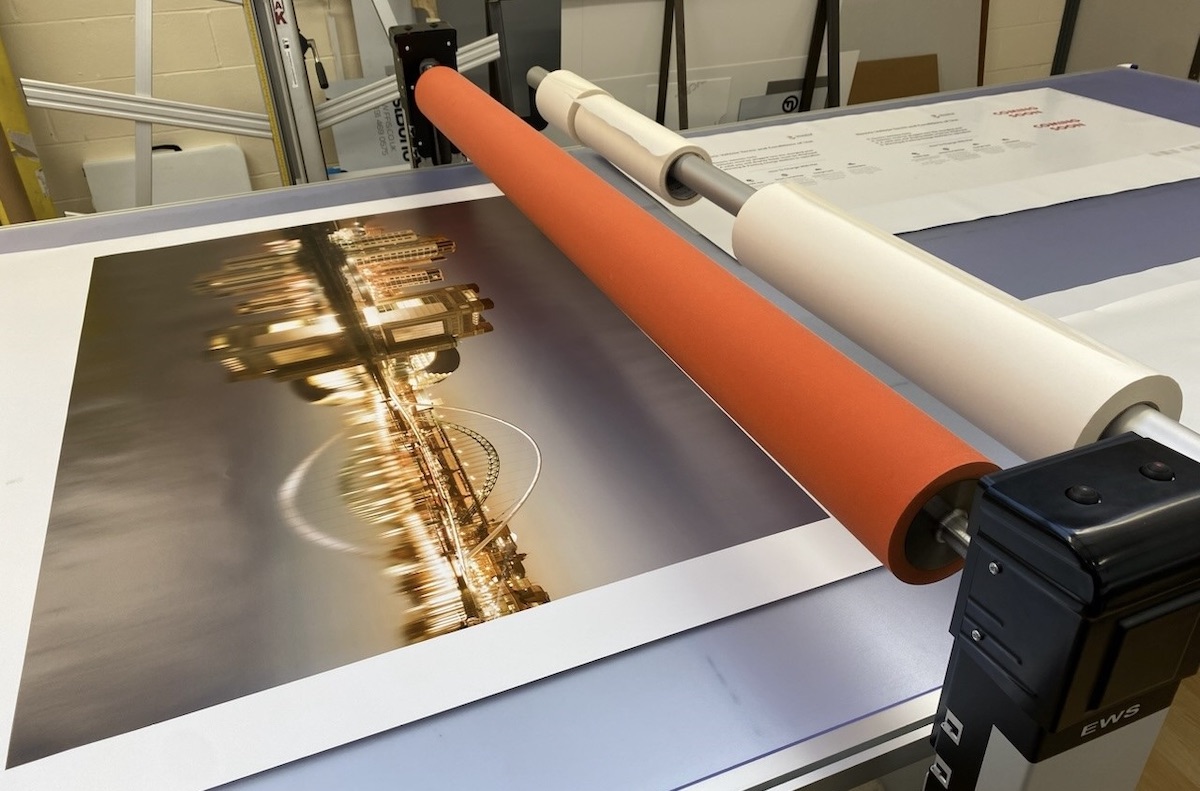

YPS provided a Mimaki CJV150-130 integrated print and cut machine and the Moditech Electronic Workstation (EWS). “This solution had an immediate impact. Almost like having an extra person in the team,” says Stewart, adding, “The two machines work perfectly together. Tasks like cutting and laminating a print, which used to take 10 minutes or more, now take a few seconds. They have revolutionised our operations and have allowed us to deliver a lot more work directly, making us more profitable and ensuring the customer is happy. The Mimaki and the EWS are great machines to use. The EWS’ ergonomic design means we can easily reposition every part of it to be more comfortable and practical for the user. We love it.”

Georgia Brown, Managing Director of YPS, adds, “The Moditech EWS really is a very special product and one that we are proud to be able to offer to our customers. Everything about the design of this machine is aimed at improving the overall user experience. It is elegant, safe and incredibly user-friendly. We are delighted to see how much Navigator Signs appreciates this fantastic solution which combines the Mimaki printer/cutter and Moditech workstation, which has significantly increased productivity, efficiency and profitability.”

Increased production

Since purchasing the EWS, Stewart has found that the company has been able to increase turnaround speeds and be able to deliver a much broader range of solutions for customers fast and more cost-effectively. “One client recently rang at 8am asking for an urgent cut vinyl job. Before our new machines, at least, this would have taken us until the end of the morning to have delivered. But we had the job printed, finished and despatched to the customer by 9.15 this time! You can’t put a price on the level of customer satisfaction that gives,” says Stewart.

Success often breeds success, and Stewart is already finding he needs even greater print capacity to cope with increased business. “We pride ourselves in offering a varied array of signage solutions. Fabricated letters one minute and cut vinyl the next. In particular, thanks to the EWS and Mimaki solution, we can now react faster, allowing us to win more and bigger contracts. This also gives us the scope to plan our growth, and we will soon need larger printers and other machines to meet demand.”

He concludes, “It’s a great problem to have, and I am delighted that we now partner with a company like YPS that can provide the technology and equipment to support and develop our growth for many years to come.”