Melony Rocque-Hewitt finds out how Press On Digital Imaging created stunning chrome effects for a well-known London department store’s windows.

Every year during the build-up to Christmas, I would be taken to London specifically to see the Oxford and Regent Street lights and to view the glittering, fairytale shop windows of the capital’s most famous department stores. Three decades or so on, the Christmas windows beckon still, spreading their own brand of magical glamour and consumer seduction.

One company which has been behind the production of some of the most alluring store windows in the capital is Press On Digital Imaging (PODI), which this year output beautiful window graphics for one of London’s landmark department stores.

“We have a very good relationship with this eminent London store. We work directly with is the team there. The design department calls us in, gives us an idea of what they want to get across, shows us their mood boards, presents us with images. That way we really build a picture of how they envisage the end result to be. We go away and devise a way for that vision to be realised. It’s as simple as that,” says Press On founding partner and managing director Andy Wilson.

“The client isn’t in the least bit interested in what technology we use do the job,” continues Wilson, “what they want to see is the end result. We don’t always come up with a solution straight away. We often collaborate with our trusted materials supplier Paul Noble at All Print Supplies who we have been working closely with for the last seven years. We discuss the brief with them and they go away and come back with samples or new materials that they think will do the trick. They are invaluable to our business and an essential partner in the way we approach our clients,” says Wilson.

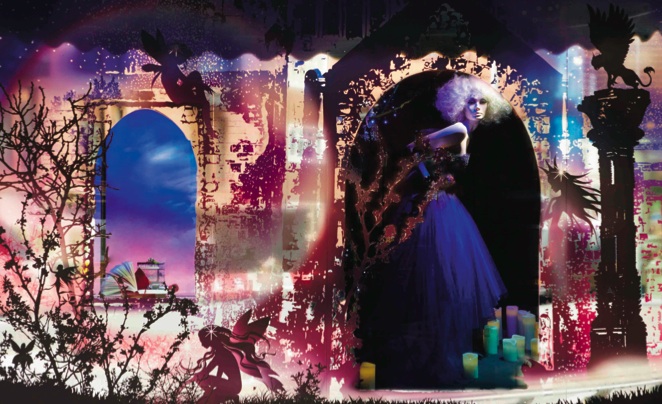

Building on some experimental window display work that was done at the same well-known department store during the course of last year, the in-store designers were keen to incorporate the look and feel of chrome, mirrors and metallics for some of their Christmas windows. The result was visible to all across several windows, each displaying metallic, graphical, ethereal, winter elements and colours.

The imagery for these displays was printed onto a chrome-effect, self-adhesive vinyl while some window sections were left unprinted and therefore acting as mirrors to reflect the window shopper into the scenes. Other sections were cut away entirely revealing the merchandise within. Together these treatments created a subtle textured look with a contemporary edge.

“Aesthetics aside, this job was quite an interesting one for us,” says Wilson. “We used latex inks printed onto a standard chrome vinyl from All Print Supplies – it wasn’t even an accredited latex material but the results are excellent – the client was really happy. “Latex inks are translucent and very glossy and gave the right weight and feel to the designs and of course, the great thing about them is that they can be used externally.”

And for this job this is exactly what was required - an external vinyl that could be applied to the windows, still look good and be tough enough to withstand the onslaught of Christmas shoppers thronging Knightsbridge. “Whatever we were using had to withstand external pressures and achieve the desired aesthetic. The latex inks were perfect for that as was the vinyl sourced for us by All Print Supplies.

“With this store there’s no room to apply graphics inside the windows. Also there is transparent bomb film covering the glass internally and you can’t put anything on this as it will get damaged, hence the need for external application,” says Wilson.

Metallic printing was for a long time the holy grail of the digital wide-format print industry. “Every Christmas,” he says, “came requests for glitter and chrome work – which was impossible to carry out using the company’s solvent printers.

While there are digital wide-format printers that print with metallic inksets (think Roland and Mimaki for starters), Wilson says the amount of work Press On does involving chrome and metallics, just didn’t justify the purchase of such kit. “Instead we had to look at our existing arsenal to see how we could come up with a solution that would work,” he says.

Last year one of the company’s high profile jobs that involved printing onto chrome vinyl was for media company Limited Space. Here Press On was asked to create fantastic chrome effects to apply to prominent lift spaces in shopping malls up and down the country. This was the nationwide release of the film ‘Mirror Mirror’ starring Julia Roberts.

For this job the company used one of its roll-to-roll flatbed printers, laying down white ink before printing onto the substrate. “It was a very effective and eye-catching part of the film’s promotional campaign. Our client was really pleased,” says Wilson.

He and his partner formed Press On Digital Imaging in 2000 when it burst onto the scene as a brand new wide-format digital print company. “My partner Nigel Webster and I had worked within the litho print industry, screen printers, repro houses and the like. We could see the opportunities afforded by wide format digital print technology but we were working in environments that saw the technology as a threat to old skill sets. We decided enough was enough. We wanted to be creative partners not just jobbing printers and take advantage of the potential that wide-format offered.”

Initially the company was running an e-stat printer and started offering billboards to the media industry. Once this space became saturated the company moved into servicing the boutique end of the retail market. Once this became populated by other LFPs, Press On turned its attention to signage.

“We service a number of diverse sectors within the digital print industry, so we have broad knowledge of a number of different areas. That diversity works very well for us,” says Wilson.

The company’s plant list resembles a history lesson in the development of digital printing. Following the e-stat printer it bought two Encad machines, a Xerox X2, and a raft of HP kit followed including HP5500 and Z series, plus a Roland Soljet and Oce Arizona. Five years ago two roll-to-roll UV flatbeds were installed. These were joined a year ago with an HP 850 latex machine, which has since been joined by another three latex machines. During the summer of 2012 the company installed a Kongsberg XP cutting table, replacing a nine-year-old Zund cutter.

The Kongsberg has allowed the company to do everything quicker, “What would have taken five days, now only takes one,” says Wilson. The arrival of latex capability has opened up the world of vehicle graphics. “We’re outputting 100,000m2 of vinyl for vehicle graphics and last year printed, cut and wrapped over 3,000 vehicles. We can print, laminate and cut 20 Vauxhall Vivaro vans in 12 hours,” he enthuses.

Wilson credits HP reseller City and West End for the last nine years or so for guiding his company into buying the right kit, which has proved very successful for the business.

As far as the future is concerned Press On is keeping an eye on moving screen technology with a view to integrating this into its services creatively. We look forward to viewing its store window work for future Christmases.

www.presson.co.uk