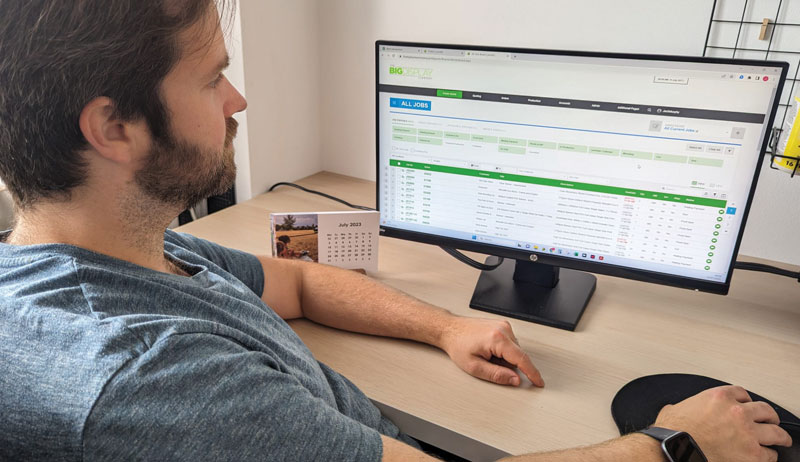

The Big Display Company has swapped its Shopvox estimating and production system for a PrintIQ solution. So has the move been worth the time and money? I asked its marketing director Jack Murphy…

Want a first-hand account of a wide-format print PSP buying into a new software package to improve workflow and efficiencies? Thought so, which is why The Big Display Company marketing director Jack Murphy’s here tells his story in his own words.

He starts by explaining: “We are a large format printing company based in Slough. Our equipment is predominantly HP latex, with a 2.5m hybrid, two of the 3.2 HP 3600 and two of the 1.6 HP 800, but we also specialise in textile with an Agfa Avinci 3.2m and a Kleverik calendar.

“We used Shopvox.com for four years for our estimating and production board. When each job was approved we would print off the work order for each material and staple the artwork to the back. Some jobs would end up having 10 - 20 pieces of paper due to the complexity of the order/number of artworks/notes etc.

“Although Shopvox is a good platform, it hadn’t developed much over the time we’d been using it and they weren’t very receptive to feedback, so we knew it was time for a change. It was also clear that it wasn’t the right software for us to go paperless, a long-term goal of ours. So, over the next year, we researched different options, including all the usual suspects, but we couldn’t find anything that directly catered for wide-format. All of the long-standing software packages on the market were too focused on small-format, with a workaround for wide-format. That wasn’t good enough for us.

“We came across PrintIQ and it looked like the best option for our set-up. Its core was set in small-format, but they had put a lot of consideration into the working practices for wide-format and the ways that jobs are estimated (ink per square metre costs/material per square or linear metres/combining multiple hardware components/labour costs etc). After seeing a demo it was pretty clear to us that it was the right software to go for.

“From the initial meetings to go-live was about 12 months. It was a long haul because we had to rethink how we look at our costing and our production processes. Every nut and bolt needed to be accounted for, the timings for each process needed to be factored in, and every product needed to be built from the ground up. It also required every order to split into individual jobs, which wasn’t something we were used to from an estimating or production point of view.

“It wasn’t easy getting the software ready because the level of detail required was so much higher than we had readily available, and the product set-up was very complex to achieve what we needed the system to do. There were plenty of occasions where it just didn’t seem like the benefits would be worthwhile because we had to make so many compromises from the easier processes we had in place. But we kept the faith because we needed to make that move to being paperless, and we needed better accuracy with our estimating. So, although we knew we would lose out on the shortcuts we were used to with Shopvox, this was something we needed to do.

“I had gone into the ‘go live’ date worrying that production would struggle with going completely paperless - there wasn’t a midpoint between running paperwork as we had always done, and being completely digital, we just had to take the dive. After a few days of niggles the production department took to it better than I could have ever hoped for and they have completely embraced an entirely paperless process, from artworking through to dispatch.

“Sales has been much harder to implement because although there are some elements which are much quicker - particularly complicated products that have a lot of finishing requirements, or quotes with multiple quantities - there are some parts of the system which are a lot slower than what we’re used to - like changing an order once it’s been booked in, or quotes with a lot of different sizes in the same material. The team have now got their heads in the right place and are doing a great job with processing even the most complicated orders. More importantly they are able to see the benefits that the system brings to the whole company.

“Now we’re several weeks into it there are still a lot of workflows we’re finalising and we know it’ll always be a work-in-progress, but it has bedded-in really well and I couldn’t imagine going back to how we were running the company previously. Realistically, we couldn’t have gotten to this stage without the continued help and support of PrintIQ, and I’m excited to see how the platform will develop over the coming years.

“The biggest cost for us in the whole project was time - it took much longer than we expected - but it was worth it given the result.”