Cyrus Norton has plans to double Digital Factory’s £2m turnover by 2021 and central to them are new Durst P10 200 and Durst Rho 312 systems. For the managing director of the Farnborough, Hampshire, wide-format specialist, the new printers are the final stage of a £1.7m investment that supports a move to grand format production.

The spend includes a move last March into purpose-built premises. Norton said: “I set up the business in 1998 with a partner in his garage. Over the years we have grown into bigger and bigger premises. Since I took over the whole company I have been looking at ways to continue this growth and decided a move to new premises would help us take a fresh approach.”

He added: “I wanted to create the best possible production environment. We have reviewed everything from order intake and planned workflow minimising human touchpoints to the fastest and most effective production solutions. The Dursts have been critical to that. They also allow us to enhance our grand format capabilities.”

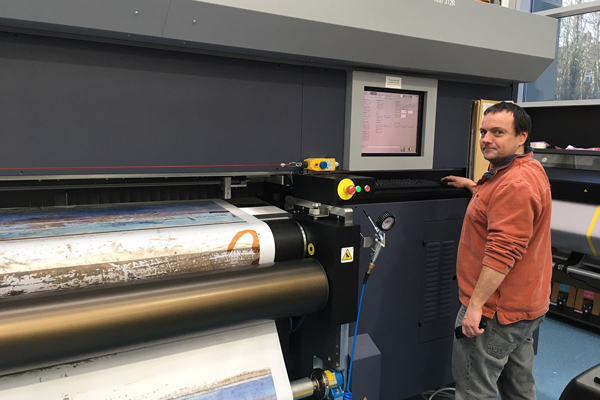

Norton expects the business to harness greater production capacity and double turnover in within four years, with minimal staff increase. “Already the P10 200 has doubled output and Rho 312 is at least 65% faster. It used to take us two hours to run two rolls of wallpaper, now it is just 45 minutes,” he said. “The print quality, ease of use, speed and system build will help future-proof our business. We can enhance the quality of our work and increase our production capacity. They give us production flexibility.”

Digital Factory first installed a Durst P10 160 in 2012 and it was up to capacity within six months. To maximise the quality and productivity Norton reviewed the ink sets and substrates. That is why he knew what he wanted when it came to choosing the Durst P10 200 2.0m wide UV curing 6-colour flatbed with white underscore and overscore and the Durst Rho 312 3.2m wide UV curing 6-colour roll-to-roll printer with white underscore and overscore.

“We had everything set up the way we needed to best serve our client base and just wanted to be up and running,” said Norton. “80% of our work is for agencies and we have built this business on the back of Durst printers. I expect them to easily pay for themselves within three and a half years.”