Claire White, member of the POPAI sustainability council and specification consultant for Antalis, looks at the issues the print sector is facing in terms of sustainability.

If there’s one thing that’s clear when it comes to tackling climate change, it’s the need for collaboration. In the print industry, that’s beginning to happen, with PSPs, suppliers and various other links in the supply chain working to minimise print’s impact on the environment. But we know there’s more to be done, and that greater understanding of the issues is the cornerstone to building a more sustainable future.

Antalis is one supplier working to provide guidance and empower companies across the print industry - and in turn their clients - to transition to more sustainable choices and practices.

Claire White, specification consultant for Antalis, points out that with the global production of plastic having tripled in the last 25 years, most countries are driving the reduction of single-use or time-limited plastic objects, and that the visual communications sector - which absorbs 1% of the world’s plastic production - has a responsibility to encourage the use of greener materials.

“Part of the historic problem has been that plastic in general was considered a revolutionary product due to its practicality but now we need to reduce the impact it has clearly created across the globe,” she says.

What does this mean in practice? We all understand change needs to happen but often it is simply knowing where to start the process that can often be the biggest challenge. As a direct result, Antalis at the start of this year, published a manifesto outlining its commitment, alongside a support framework of products and services, to guide its customers towards a more eco-responsible future.

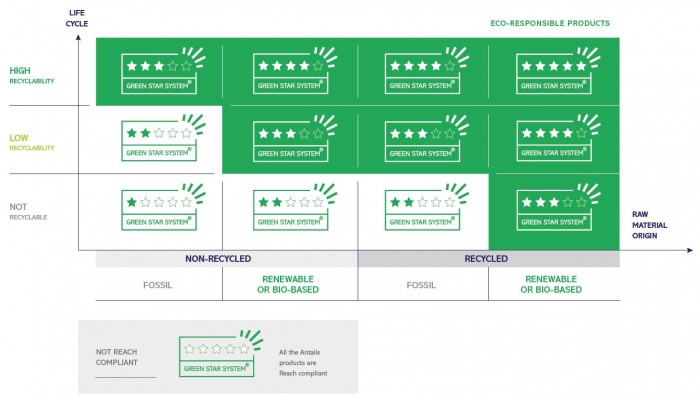

The Antalis Green Star System makes it easy to identify sustainable products by taking into account two key factors - raw materials used, and recyclability at end of life - and attributing products with a rating from zero to five stars.

The raw material element of the framework categorises products by their origin into either fossil fuels (hydrocarbons that are not derived from plant sources) at the lower end of the scale, to renewable and bio-sourced materials (plant-based), through to recycled materials at the top end of the framework. The life cycle axis then classifies whether products are unable to be recycled due to their composition, through to products that have high recyclability such as single material polymers like polypropylene. It is Antalis’ strategy to achieve 75% of visual communication products sold to be rated three-stars or above by 2030.

The sustainable framework includes:

- Responsible sourcing: engaging in developing responsible end-to-end supply chain management. Antalis’ Antrak online platform was designed to collate, centralise and analyse supplier information relating to regulation, product traceability and CSR commitments.

- Green Star System: assists customers to easily identify and support their transition across to eco-friendly product options.

- Sustainable products: a wide portfolio of eco-responsible alternatives for most indoor and outdoor visual communication applications.

- Carbon offsetting: working alongside leading schemes to ensure that carbon credits purchased fund the best projects in the UK and worldwide.

- Waste management support: working with others in waste management services that can audit an organisation’s waste, help reduce it and advise how best to recycle, use or dispose of each material type generated.

With the pressure mounting from consumers, substrate manufacturers are also responding with an ever-growing range of materials to meet requirements. For instance, Xanita board (available exclusively in the UK from Antalis) is a lightweight yet strong closed-cell fibreboard manufactured from post-consumer waste. Katz board is also 100% fibre-based, made from natural ground wood pulp and high-quality coated paper liners. Both options are environmentally friendly alternatives to the use of PVC and PUR foamboards and are 100% recyclable.

White says that “as consumers gain knowledge of what becoming eco responsible truly means, the type of questions we are being asked has shifted. It used to just be about materials and price, but now they also consider things like, ‘does moving across to a more recyclable product reduce the quality of the result?’ and ‘can you help me to offset the carbon of all the materials I use or balance the carbon footprint of my business?’.”

Carbon offsetting in action

In April of this year, the UK Government announced ambitious climate change targets to reduce emissions by 78% by 2035 compared to 1990 levels. Of course, with such an ambitious Government target to reach, print specifiers/buyers will naturally want to source sign and display products that are made with sustainable and recycled raw materials, but may have to wait for the manufacturers to respond and adapt the product compositions to offer more options. However, they can take first steps towards the change by carbon offsetting the unavoidable carbon dioxide emissions generated from the products available today.

Antalis offers carbon offsetting for all products, including wide-format media. Working alongside two partners - Forest Carbon and The World Land Trust - carbon credits purchased help to fund projects in the UK and worldwide.

However, one of the biggest challenges occurs at the ‘end of life’. There are so many great substrates across wide-format media but little supporting education provided to the end user, often in the retail or hospitality sectors, who is expected to identify and dispose of materials often without prior training to understand which recycling bin to put it in.

Recyclability and waste management:

Aligned with the waste hierarchy (reduce, reuse, recycle), sign makers and large-format printers naturally want to minimise the amount of waste produced and often the challenge is storing sufficient segregated materials that make it economical for waste management companies to collect for recycling.

Recycling companies do have options for recyclable plastics, but they are presently not all commercially viable, mainly driven by low volumes and geography. If companies invest in purchasing easier to recycle materials, making them more mainstream, it will in turn increase volumes and make recycling at the end of life more attractive for waste companies, reducing landfill and incineration.

Antalis is keen to support companies interested in improving their waste hierarchy practices. The company works alongside a leading waste management services provider to help businesses understand and work through some of the challenges around recycling volumes and segregation of materials.

As we’ve said, collaboration is key to tackling climate change, and White is a member of the POPAI sustainability council which comprises a group of industry professionals all working together to make a positive difference. To determine the current realities versus perceptions, and what the challenges of recycling products currently are, POPAI and Stevelister.com are leading a research project to gather insights across the UK and Ireland. Antalis is one of three headline sponsors, along with HH Global and Linney.

The research focuses on the grocery and pharmacy beauty retail sector, specifically looking at in-store point-of-sale marketing, temporary product displays and packaging recycling. Using a combination of desk research, senior level brand and retailer interviews and back of store level investigation, the group aims to establish industry benchmarks and provide recommendations for the industry to improve its recycling performance.

By pulling together to provide education, and hopefully solutions to the outstanding issues, print can become an ever more sustainable option.