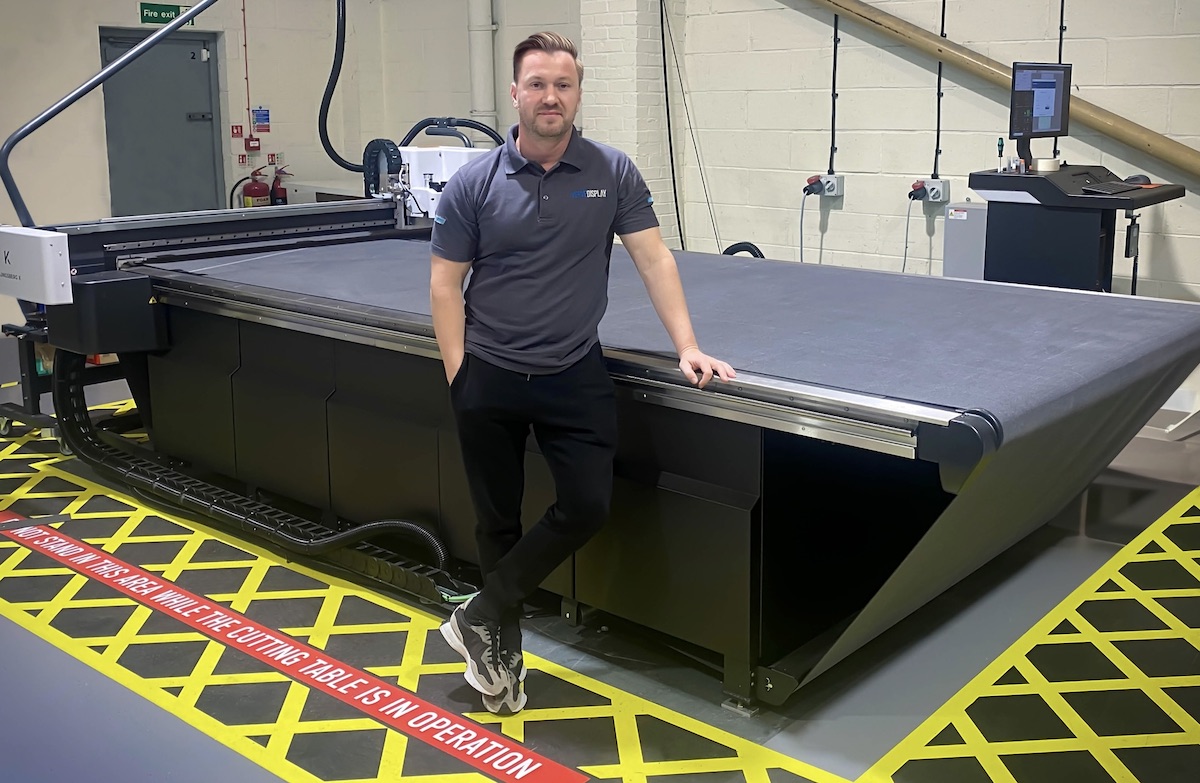

Verve Display, the Harlow-based bespoke experiential events print specialist, has invested in a Kongsberg X24 digital cutting table from CMYUK. The new finishing table replaces the company’s defunct Zund cutter that it’s been running for over 8 years. A recent purchase of a new 3.2m wide UV roll to roll printer was also a key driver for the business to update its printing and digital cutting capabilities to maintain the highest quality and speed of its workflow.

“The Zund has been a great piece of kit, and we certainly got a lot of work out of it, but we knew it needed upgrading. We looked at various options because as we had not invested in that side of the business for a while, we wanted to see what was out there,” says Verve Director, David Blackholly.

After considering solutions from a number of well-known manufacturers, Verve senior management was persuaded by the versatility of the Kongsberg X24.

“The Kongsberg was the right choice for us. We believe it will do everything we need it to do and more. Having a conveyorised system unlike the fixed bed we had before was very important to us. We were also impressed by the ease of changing the router,” says David.

Verve Display is an established company of 20 staff that makes a large impact. Celebrating its 20th anniversary this year, it began as a general wide format signage printer, but over the years has evolved into specialist bespoke event build and branding. Verve is also massively involved with its sustainability drive and greener solutions, both its machinery, materials and especially its Zero to landfill commitment. Currently clients include The 02 Arena where it created all graphics for Elton John’s 10-night takeover stint of his Goodbye Yellow Brick Road tour, Capital Radio’s Summertime and Jingle Bell Balls, The Brit Awards, Classic FM Live, Great Ormond Street Hospital, ATP Tennis with Queens and The OVO Arena, Wembley, plus many more.

Verve has been buying its sustainable PVC-free materials from CMYUK for the last couple of years, and this positive relationship also had some influence over the Kongsberg purchase.

“It was important to us to work with a partner like CMYUK because the transaction goes beyond the sale. We knew having the Kongsberg X24 would be a learning curve for us, and we would need support going forward. Even after formal training, if we have questions i.e., certain settings for a particular type of material, we can just pick up the phone to the technical team at CMYUK – they are friendly, helpful, and always there. The other big bonus is when we recruit new staff, we can send them to the CMYUK demo centre for training on the Kongsberg – all free of charge, which is really good to know,” says David.

The installation of the X24 almost immediately impacted the company’s working processes. Prior to its arrival a 1300mm plotter was used for vinyl cutting, now all cutting including kiss cuts are directed through the Kongsberg as its fast, efficient, and highly accurate.

Says David, “Our confidence with the cutter is growing. We’d like to push the creative side more to compliment the nature of our bespoke solutions we offer clients, to use it for bending of Di bond or to create washout effects for example. We’re experimented with this all the time, when a job comes in, it has to be perfect. We’re not just cutting out a shape, we’re producing products.”