If you’re looking for a sheet plastics distributor that can offer you a whole lot more, then you should be talking to Nick Warne and his team at NE Plastics. “Following our successful debut at FESPA in London, earlier this year, we have experienced a significant growth in sales; not only in our core business of flat sheet but also for our new roll media range and for trade fabrication work where good quality and fast turnaround is our mantra. “

PLASTICS DISTRIBUTION COMING OF AGE

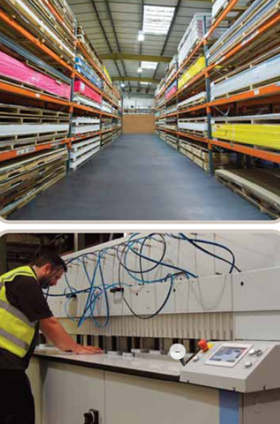

“I started the company in 1992 in South East London and it has grown over the past 21 years by using our in depth knowledge of materials, what they do and where to source them.” The main distribution centre in Sidcup, South East London has flourished by stocking trusted major branded products produced by the likes of Perspex™,Foamalite™and many other well-known manufacturers, with over 2000 products readily available for distribution at competitive prices including our own brand Alliance ACP™Aluminium composite panel.

TRADE FABRICATION SERVICE

We stock and distribute cut to size products and also provide a Trade Fabrication service on site. This is a powerful offering, both being a stockist and having a fabrication service under one roof, meaning that our customers benefit from a fast and efficient turn round of their orders, however complex.

We run our own in-house fleet of vehicles which can cater with anything from 6m sheets down to a simple leaflet holder. We also work with strategic transport partners to be able to offer a national and international service.

WE LISTEN

Our aim is to listen to challenges that our customers face and become part of their team. Listening to our customers’ requests, we have always tried to stock the mainstream products but also the unusual and were the first company in the UK to hold 4mtr x 2mtr sheets of foam PVC and have added other products to this over the years. We stock our own branded ‘BIFLUTE’ fluted polypropylene in a massive 3050x2440 mm size and have recently added a range of coloured acrylic mirror in 3050x2050 mm, another UK first.

Being one of the few companies actually holding stock in the London area, we have recently started stocking a range of roll media products to add to our next day, and very often, same day delivery service. We have teamed up with Ilford™; a name fondly remembered by those with a photographic background but who are now at the forefront in developing their range of large format digital products with their Omnijet, Aquablock and Trans Media products.

Shortly to be added to the range will be self-adhesives, wallpaper, pop up materials and back lit.

THE HOLY GRAIL….

The traditional market for flat sheet plastics has gone through some considerable changes over the years. Before large format DTM, everything was mounted and the problems tended to be thickness tolerance issues and outgassing where moisture bubbles were formed between the graphic and the substrate. Those issues have now been largely eradicated and it is now a question of getting good ink key, without static and marking, where the inks used are incredibly transparent. This has seen the emergence of a range of ‘PRINT’ materials where the Dyne level has been adjusted to ensure good adhesion to substrates that are sometimes notoriously difficult to print to.

NEW PRODUCTS

We at NE Plastics are well ahead of the curve and have the benefit of being a distribution partner for Foamalite, now a fully owned division of 3A Composites, a company well known for being at the forefront of product development. They have reformulated all the Foamalite products and taken them to a new level of printability, as good, if not better than any of the other products currently available. The full density Foamalite Premium and the lower density Foamalite Express products both have new green film with the same anti- static, non-marking properties. They have also recently relaunched their polyester products, their A-PET now under the Lumex-A brand and their PET-G under the Lumex-G brand. Both products again have excellent printability and the Lumex-G can be ‘V’ grooved allowing the product to be cold bent after printing. This was clearly demonstrated on the post-it note desk block holder that they gave away at FESPA and are still available should you want one, please just call the sales office.

ENVIRONMENTAL ISSUES

The other big thing in the plastics industry has been the Green issue. For years everyone was searching for the Holy Grail, a product that would biodegrade, this saw the growth of a huge variety of paper based honeycomb centred type boards but since the 2012 London Olympics, the emphasis has been re-usability and now anything that ends up in land-fill is an issue, not just for the planet but also financially as land fill taxes continue to rise. This is where products like Foamalite plus come into their own where the black centre contains an element of recycled product.

OUR SECRET WEAPONS

Equipment: At NE Plastics we have always invested in the best tools for the job which started with a Schelling beam saw and a Striebig wall saw and more recently a 3mtr x 2mtr Tekcel Router and a 3mtr flatbed Diamond Polisher, the largest machine on the market today and it is with these machines that we have made a name for ourselves as offering the best quality with the shortest possible lead times.

Equipment: At NE Plastics we have always invested in the best tools for the job which started with a Schelling beam saw and a Striebig wall saw and more recently a 3mtr x 2mtr Tekcel Router and a 3mtr flatbed Diamond Polisher, the largest machine on the market today and it is with these machines that we have made a name for ourselves as offering the best quality with the shortest possible lead times.

Fabrication: The trade fabrication division started about 4 years ago following the growth of the lightbox and signframe business and edge polishing service. With the arrival of Alan Smith, our Fabrication Manager, who brought with him 35 years of expertise, we now have a skilled and well equipped team. We encompass most plastics processes so we can offer anything from a line bent tent card to a museum quality display case or an elaborate POS unit. This additional service allows our customers who, beforehand, would probably have had to say, “No, we can’t do that” to their customers, are now in a position to take on all sorts of other work, knowing that it was in safe hands and being done by someone that was not going to jeopardise their customer relationship. This has allowed them to significantly grow their businesses.

CRM: To improve contact with our growing family of customers, we have invested in a state of the art fully integrated CRM system. This is being linked into our accounts and stock system so that, very shortly, all of our customers will be able to log on to their own account from their computer, tablet or ‘phone and access their usual discounts and terms and place their orders 24/7. This will also coincide with the imminent launch of our new website which will also be embracing all forms of social media.

Customers: However, our most important secret weapon is our customers. NE Plastics has become a trusted partner over the years for many established and successful businesses. Our customers have been our best sales force, recommending our service to others in the industry and their feedback keeps us innovative and relevant.

We hope that businesses in the industry will see the real power of our offering and give us a try in the future. We are always available by phone, email and now on the web! Let’s see what we can do together, if it’s possible in plastics then we can make it happen.

{jathumbnail off}