The trend in laminators is toward entry-level models but there’s still a need for top of the range laminators such as this model say users.

Since the advent of UV printers and their ability to print direct to board substrates we don’t tend to hear much about laminators. Yet, they are still essential for finishing solvent and aqueous prints. The obvious use is to mount these prints to boards, which a great many people are still doing. Laminates are also used to add protection to a print, usually from the effects of UV light, but also protection from weather for outdoor signs, and from scratching and vandalism for displays in general. But there is a wide range of laminating films for different effects. This includes changing the texture of a print or adding a glossy or matte finish. On top of this laminates can also be used to enhance the colours in an image, or to add special effects such as frosting.

Laminators have had a reputation for being difficult to use because of the need to control both temperature and pressure. But in recent years manufacturers have made a determined effort to develop more intuitive laminators that are easier to manage. This month we’ve been looking at the Seal 62 Pro, a top of the range 1.6m wide laminator that has been designed for heavy duty use.

Contour Direct, a large-format graphics bureau based in Greenford in Middlesex, which takes on a range of wide- format work, including banners, window graphics and general signage. Its laminator is used for mounting self adhesive vinyls to Foamex and other rigid substrates for retail and exhibition use as well as for building site hoardings. Managing director Ian Sweeting points out that even if he printed direct to board he would still need to laminate anti-graffiti films to things like hoardings.

Sweeting says he started off with a Seal laminator and although he regularly looks at other options, he always ends up buying another Seal. He explains: “When you are in business, you just need consistency. It doesn't have to be the fastest machine, you just have to know how it works. I know that it will do four to five metres per minute mounting which is good as you don't want things coming out the other end faster than you can dress the graphics.”

Sweeting says he started off with a Seal laminator and although he regularly looks at other options, he always ends up buying another Seal. He explains: “When you are in business, you just need consistency. It doesn't have to be the fastest machine, you just have to know how it works. I know that it will do four to five metres per minute mounting which is good as you don't want things coming out the other end faster than you can dress the graphics.”

He says that the machine is easy to use and that all the controls are well thought out and can be reached easily from both sides of the laminator. He adds: “The operators know how to use them and how to get the best out of them and how much heat and pressure to use.”

Contour only uses pressure sensitive films but Sweeting says that you still need to have a heated top roller to make sure that the glue goes completely clear. He adds: “If you have an uneven surface like plywood or MDF, then a little bit of heat enables the glue to get into the depressions.”

Sweeting acknowledges that the price of the Seal 62 Pro S is fairly steep and that there are cheaper laminators available, but he now has three of the 62 Pro laminators, including one that's been going for over ten years.

He points out that it’s difficult to test a laminator so you have to be sure of what you are buying, adding that it can be a false economy to buy a cheaper one: “If a laminator doesn't mount the graphic perfectly the first time then you have to reprint that graphic so the costs can soon mount up.”

He says that as with any mechanical device they occasionally need servicing, such as when a chain wheel stretches, which can mean the laminator being down for a day. But Sweeting says that this happens so rarely, typically once every 18 months, that he doesn't use a service contract, adding: “There's never a problem in finding parts when an engineer comes and the cost is reasonable.”

Tony Moore, who handles production for Concorde Graphics, reports similar experiences with the 62 Pro, saying that nothing ever goes wrong with it. He says that where you can have problems with dual heated machines where elements go, there's nothing to go wrong with the 62 Pro S.

Concorde handles a range of general sign work, taking on anything from a one-off print to a building wrap, and its installation. Last year Concorde set up an in-house photographic studio. The company uses the laminator for mounting photographic prints and vinyls to board as well as general laminating using pressure sensitive films. Moore says that the prints come out perfectly every time, adding: “It does everything you need it to but it's far easier than a lot of the other laminators that are out there.”

Indeed, we didn’t find anyone who had a bad word to say about the Pro 62. It's definitely not the cheapest laminator around, but its ease of use and overall robustness appears to justify this.

About the product

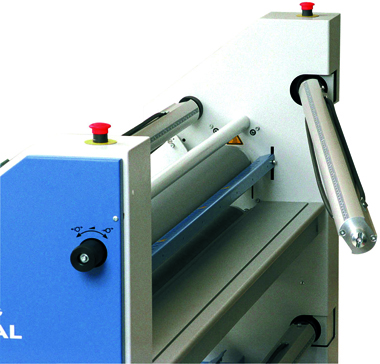

Seal has a wide range of laminators for different uses but the 62 Pro S is close to the top of the range. It’s a popular model, aimed at busy production environments, is 2220mm wide and takes media up to 1575mm wide and 40mm thick. It has a single top heated roller, which has a maximum temperature of 140 degrees and there are automatic cooling fans to help with longer shifts. It has a maximum nip pressure of 2.5N/mm, but with manual nip adjustment. The table has built-in tensioning rollers and a flip-down guide to help feed media into

the machine and there are slitters on the other side to trim the output. It can run at up to 6mpm. It comes with a foot control for hands-free operation and can be controlled from either side of the machine.

The 62 Pro S is designed to cope with a range of media, both pressure sensitive and heat activated. It can cope with most applications from mounting to rigid boards to straightforward lamination.

The machine costs around £11,000. There’s also a model with dual heated rollers, the 62 Pro D, which costs around £18,000 but can also handle encapsulation.

Alternatives

VIVID

Vivid makes a number of laminators including its own Easymount range. This includes the 1600 Single Hot, which takes media up to 1650mm wide. This has a heated top roller, using internal infrared heating, and can laminate at up to 6mpm. It has a digital control panel, with a separate foot pedal and the pressure can be manually controlled.

Vivid also sells the Polarsign range of laminators, billed as a more affordable system. Maximum width is 1600mm and it can mount materials up to 20mm thick. It has a single heated roller, and can reach a temperature of 60 degrees and laminate at up to 6mpm.

KALA

The Kala range of laminators, which come from France, are a more entry-level alternative though the top of the range Atlantic features heated top and bottom rollers that can be independently controlled up to 140 degrees. It’s sold in both 1080mm and 1650mm wide versions. It takes boards up to 25mm thick and can run at up to 3mpm.

ROYAL SOVEREIGN

Royal Sovereign makes several entry level laminators but the top of its range is the RSC-1650LSH. This takes media up to 1650mm wide and up to 500 microns thick. It has a single heated roller with a temperature of 50 degrees and runs up to 5mpm.

{jathumbnail off}