Coker Expo owner and CEO Ashley Coker is doing it. Should you?

With the ever-increasing demand for customisation, 3D parametric modelling can help a PSP walk the walk. So says Coker Expo owner and CEO Ashley Coker, who has so far invested over £30,000 in creating an attractive proposition for clients and the business alike.

Coker explains: “In simple terms, parametric modelling is a method of creating 3D models that can be modified by changing specific parameters or variables. The use of software to enhance the process of providing artwork for print is an essential aspect of this approach. By applying artwork to the parametric models, print companies can provide customers with a realistic preview of what the final product will look like before printing.

“In addition to being an efficient way to provide customised products, parametric modelling can also enhance the customer experience as they can be involved in the process of creating their products, whether they are using an online website or traditional sales process. The ability to see a 3D preview of their product before it is printed can provide a sense of ownership, which can lead to greater customer satisfaction.

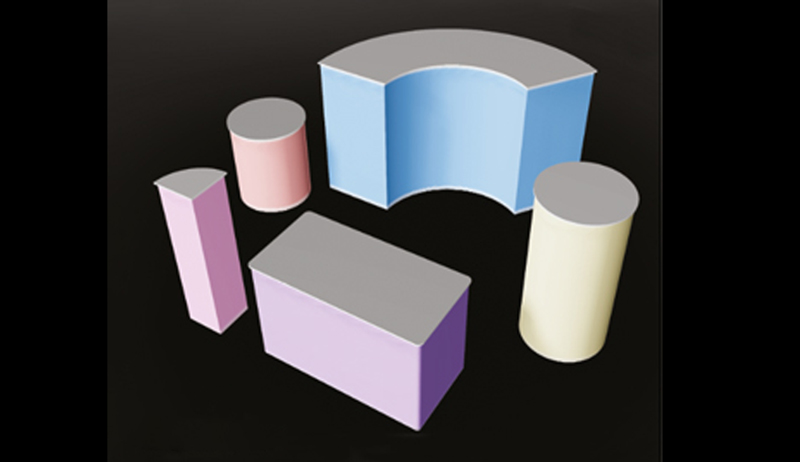

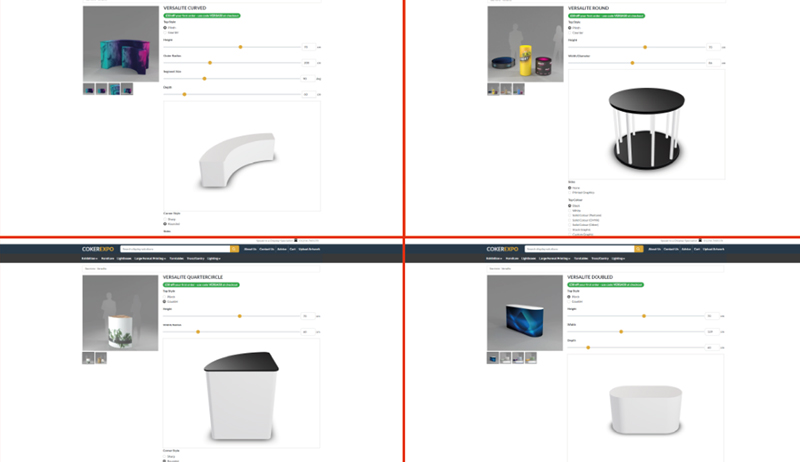

“At CokerExpo we have invested in this approach with our new Versalite range of display furniture. The furniture is manufactured in the UK and can be (within the constraints of the materials uses) any shape, any size and any colour. The CokerExpo.co.uk website already gives people the ability to configure the dimensions of their product while automatically updating the price according to their selected options.

“In the coming weeks we are launching new features to enable people to upload their own artwork files and view their customised product in 3D. They will be able to configure the face and top of the furniture with different artwork - files/colours/pred-defined templates - and even download 3D models that can be imported into other 3D design software used in more complex renders. Any optional extras are also included in the 3D model so the customer can understand exactly what they are getting. Need an internal shelf? No problem. Want rounded corners? No problem. Looking for extra supports for superior strength? No problem. Soon we hope to be able to configure ‘snap together’ models as well, so bespoke larger modular displays can be configured in real time.

“Our investment in 3D modelling thus far is in the region of £30,000, plus the work to integrate it into our website to get it in the hands of our users. That may sound a lot, but when you consider what we get from that investment the upside is remarkable.

“We didn’t start with 3D, we started with 2D models that we then extruded into 3D. Why, I hear you ask? Well, the benefit of this approach is that we get 2D cut files for our furniture range that are used to power the machines that manufacture the furniture itself. So this is full scale automation. The 2D models power the cutting machines and provide the user with exact artwork templates for their chosen dimensions. The 3D extruding process takes the exact 2D sizings and creates an exact 3D model for use by the website/design software.

“Another major benefit of this approach is our ability to provide hardware only to trade, so other printers can supply and fit their own artwork. Just let us know what size/shape/colour top furniture your clients need and we’ll get cutting.”