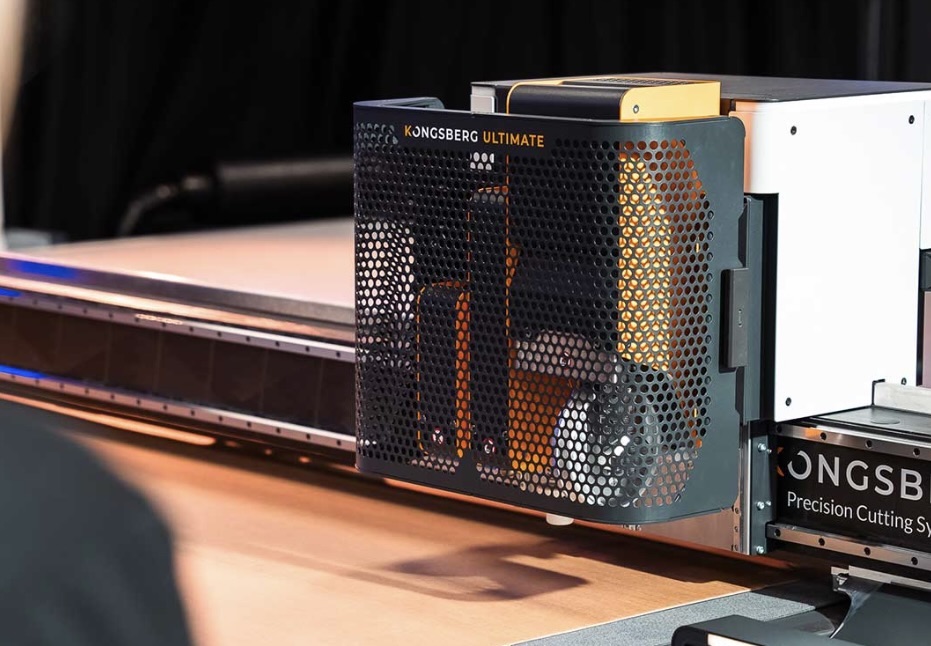

Kongsberg Precision Cutting Systems has unveiled the Kongsberg Ultimate digital cutting table, designed specifically for corrugated and display production. New direct drive technology provides up to 2.7G acceleration and cutting speeds of over 165m/min.

The Kongsberg Ultimate can be configured as a manual, semi-automated with a feeder and stacker, up to automated with a robotic material handler.

The Kongsberg Ultimate features three tool positions. Users can achieve the trifecta of cutting, creasing, and perforating of corrugated jobs without halting for tool adjustments thanks to a Dual Heavy-Duty Unit combined with a CorruSpeed tool and oscillating VibraCut Knife tools. Also, existing Kongsberg C Series corrugated tools integrate with the Kongsberg Ultimate.

Developed specifically for i-cut Production Console 3.0, a new sequencing module is designed to boost both productivity and energy savings. On its own, the Kongsberg Ultimate has a 31% productivity increase over Kongsberg’s previous best. When paired with the intelligent sequencing module, this can jump to 57% more productivity according to Kongsberg.

The Ultimate is also equipped with SmartZone, a proximity driven safety feature. The first zone slows the machine (e.g. when an operator comes closer for a visual inspection). Move closer, and the second zone pauses everything.

The Ultimate comes with a new workstation with an adjustable worktop, convenient storage trays, and a Qi phone charger. There’s a new touchscreen, an integrated storage system and a dedicated bin for used blades.